Table of Contents

Applications of 90 micron nylon mesh in Filtration Systems

90 Micron Nylon Mesh: For When Precision Matters Most

In the realm of filtration systems, the choice of materials plays a pivotal role in determining the efficiency and effectiveness of the process. One such material that has gained significant traction in various industries is the 90 micron nylon mesh. This particular mesh size strikes a balance between filtration precision and flow rate, making it an ideal choice for applications where clarity and purity are paramount. The versatility of 90 micron nylon mesh allows it to be employed in a wide range of filtration systems, from industrial processes to laboratory settings.

One of the primary applications of 90 micron nylon mesh is in the food and beverage industry. Here, the mesh is utilized to filter out unwanted particles from liquids, ensuring that the final product meets stringent quality standards. For instance, during the brewing process, 90 micron nylon mesh can effectively separate hops and other solids from the liquid, resulting in a clear and flavorful beer. Similarly, in juice production, this mesh size helps to remove pulp and sediment, providing consumers with a smooth and enjoyable drinking experience. The ability to maintain the integrity of the product while ensuring a high level of filtration makes 90 micron nylon mesh an invaluable asset in food processing.

In addition to the food and beverage sector, 90 micron nylon mesh is also widely used in the pharmaceutical industry. The stringent regulations governing drug production necessitate the use of high-quality filtration systems to eliminate contaminants. Here, the nylon mesh serves as a critical component in various processes, including the filtration of active pharmaceutical ingredients (APIs) and excipients. By employing 90 micron nylon mesh, manufacturers can achieve a high level of purity, which is essential for ensuring the safety and efficacy of pharmaceutical products. Furthermore, the durability and chemical resistance of nylon mesh make it suitable for use in a variety of solvents and solutions, further enhancing its applicability in this highly regulated industry.

Another significant application of 90 micron nylon mesh is in water treatment systems. As the demand for clean and safe drinking water continues to rise, effective filtration solutions are more important than ever. The 90 micron nylon mesh is adept at removing suspended solids, algae, and other contaminants from water sources, thereby improving water quality. Its use in pre-filtration systems helps to extend the life of downstream filters, reducing maintenance costs and downtime. Moreover, the lightweight and flexible nature of nylon mesh allows for easy installation and replacement, making it a practical choice for water treatment facilities.

In the realm of industrial applications, 90 micron nylon mesh is employed in various processes, including chemical manufacturing and electronics. In chemical processing, the mesh is used to filter out particulates from liquids, ensuring that the final products are free from impurities. In electronics, it serves as a protective barrier, preventing dust and debris from contaminating sensitive components during assembly. The adaptability of 90 micron nylon mesh to different environments and its ability to maintain performance under varying conditions make it a preferred choice across multiple sectors.

In conclusion, the applications of 90 micron nylon mesh in filtration systems are vast and varied, spanning industries from food and beverage to pharmaceuticals and water treatment. Its ability to provide precise filtration while maintaining flow rates is crucial in ensuring product quality and safety. As industries continue to prioritize efficiency and purity, the role of 90 micron nylon mesh will undoubtedly become even more significant, solidifying its place as a key component in modern filtration solutions.

Benefits of Using 90 Micron Nylon Mesh in Industrial Processes

When it comes to industrial processes that require precision and accuracy, using the right materials is crucial. One such material that has proven to be highly effective in a variety of applications is 90 micron nylon mesh. This fine mesh is known for its durability, flexibility, and ability to filter out even the smallest particles with ease. In this article, we will explore the benefits of using 90 micron nylon mesh in industrial processes and why it is the go-to choice for many businesses.

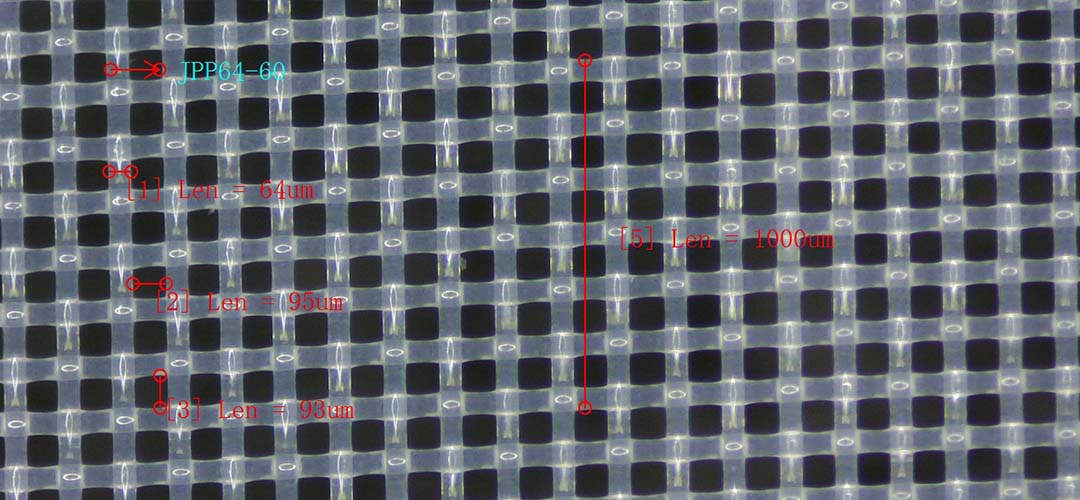

One of the key benefits of using 90 micron nylon mesh is its exceptional filtration capabilities. The fine mesh size of 90 microns allows it to capture particles that are smaller than what other types of mesh can filter out. This makes it ideal for applications where precision is paramount, such as in the pharmaceutical, food and beverage, and electronics industries. By using 90 micron nylon mesh, businesses can ensure that their products meet the highest quality standards and are free from contaminants.

In addition to its superior filtration capabilities, 90 micron nylon mesh is also highly durable and long-lasting. Made from high-quality nylon material, this mesh is resistant to tears, abrasions, and chemicals, making it ideal for use in harsh industrial environments. Its flexibility and strength allow it to withstand high pressures and temperatures, ensuring that it remains intact and effective even in the most demanding conditions. This durability makes 90 micron nylon mesh a cost-effective solution for businesses looking to improve their processes and reduce maintenance costs.

Another benefit of using 90 micron nylon mesh is its versatility. This mesh can be used in a wide range of applications, from filtering liquids and gases to separating solids and powders. Its fine mesh size and high flow rate make it suitable for a variety of processes, including sieving, straining, and dewatering. Whether you need to remove impurities from a liquid solution or separate particles of different sizes, 90 micron nylon mesh can deliver the results you need with precision and efficiency.

Furthermore, 90 micron nylon mesh is easy to clean and maintain, making it a convenient option for businesses that require frequent filter changes. Unlike other types of mesh that can clog easily or degrade over time, 90 micron nylon mesh can be cleaned with water or a mild detergent, ensuring that it remains in optimal condition for longer periods. This ease of maintenance not only saves businesses time and money but also ensures that their processes run smoothly and efficiently without any interruptions.

In conclusion, 90 micron nylon mesh is a versatile and reliable material that offers numerous benefits for businesses in need of precision filtration solutions. Its exceptional filtration capabilities, durability, and versatility make it the ideal choice for a wide range of industrial processes. By using 90 micron nylon mesh, businesses can improve the quality of their products, reduce maintenance costs, and enhance the efficiency of their operations. If precision matters most to your business, consider incorporating 90 micron nylon mesh into your processes for optimal results.

Comparing 90 Micron Nylon Mesh to Other Mesh Types for Precision Tasks

When it comes to precision tasks that require a high level of accuracy and consistency, choosing the right mesh material is crucial. One material that stands out for its precision capabilities is 90 micron nylon mesh. In this article, we will compare 90 micron nylon mesh to other mesh types to highlight why it is the superior choice for applications where precision matters most.

Nylon mesh is known for its durability, flexibility, and chemical resistance, making it a popular choice for a wide range of applications. The 90 micron size refers to the size of the openings in the mesh, with smaller micron sizes indicating finer mesh. In comparison to other mesh types, such as stainless steel or polyester, 90 micron nylon mesh offers several key advantages.

One of the main benefits of 90 micron nylon mesh is its superior filtration capabilities. The fine mesh size allows for the precise filtration of particles, ensuring that only the desired materials pass through while unwanted impurities are captured. This level of precision is essential in industries such as pharmaceuticals, food and beverage, and electronics manufacturing, where even the smallest contaminants can have a significant impact on product quality.

In addition to its filtration capabilities, 90 micron nylon mesh is also highly versatile. It can be easily customized to meet specific requirements, such as different mesh sizes or shapes. This flexibility makes it ideal for a wide range of applications, from sieving and straining to screen printing and filtration.

Compared to stainless steel mesh, which can be rigid and difficult to work with, 90 micron nylon mesh is lightweight and easy to handle. This makes it easier to install and maintain, reducing downtime and increasing productivity. Nylon mesh is also more cost-effective than stainless steel, making it a more economical choice for businesses looking to maximize their budget without sacrificing quality.

Another advantage of 90 micron nylon mesh is its resistance to chemicals and abrasion. Nylon is a durable material that can withstand harsh chemicals and abrasive materials without degrading or losing its filtration properties. This makes it ideal for applications where exposure to chemicals or abrasive substances is common, such as in the automotive or aerospace industries.

When compared to polyester mesh, which can be prone to stretching and shrinking over time, 90 micron nylon mesh maintains its shape and integrity even after prolonged use. This ensures consistent performance and reliable results, making it the preferred choice for precision tasks where accuracy is paramount.

In conclusion, 90 micron nylon mesh is the ideal choice for applications where precision matters most. Its superior filtration capabilities, versatility, durability, and resistance to chemicals and abrasion make it a standout material for a wide range of industries. When compared to other mesh types, such as stainless steel or polyester, 90 micron nylon mesh offers unmatched performance and reliability. If you are looking for a mesh material that can deliver precise results every time, look no further than 90 micron nylon mesh.