Table of Contents

Benefits of Using 500 micron nylon mesh for Heavy-Duty Applications

When it comes to heavy-duty applications that require a durable and reliable material, 500 micron nylon mesh stands out as the best choice. This versatile material offers a wide range of benefits that make it ideal for a variety of industrial and commercial applications. From filtration to separation, 500 micron nylon mesh is a versatile and cost-effective solution that can meet the demands of even the most challenging environments.

One of the key benefits of using 500 micron nylon mesh is its exceptional strength and durability. Made from high-quality nylon fibers, this mesh is able to withstand high temperatures, harsh chemicals, and heavy loads without losing its shape or integrity. This makes it ideal for applications where strength and durability are essential, such as in the mining, oil and gas, and automotive industries.

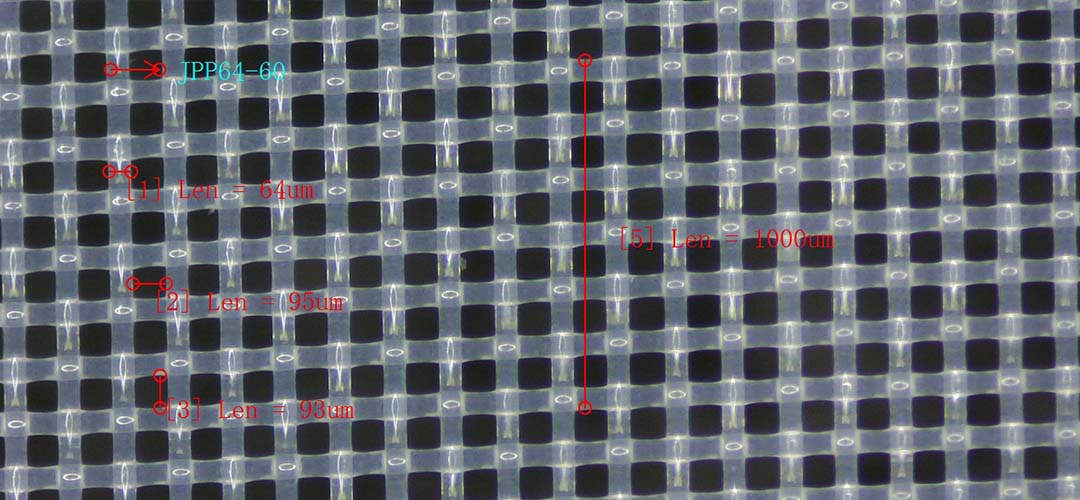

In addition to its strength, 500 micron nylon mesh also offers excellent filtration properties. The tight weave of the mesh allows for efficient filtration of particles down to 500 microns in size, making it ideal for applications where fine filtration is required. Whether you are filtering water, chemicals, or other substances, 500 micron nylon mesh can help ensure that your end product is free of contaminants and impurities.

Another benefit of using 500 micron nylon mesh is its versatility. This material can be easily cut, shaped, and molded to fit a wide range of applications, making it a flexible and adaptable solution for a variety of industries. Whether you need a custom filter, screen, or separator, 500 micron nylon mesh can be tailored to meet your specific requirements.

Furthermore, 500 micron nylon mesh is easy to clean and maintain, making it a cost-effective choice for heavy-duty applications. Unlike other materials that may require frequent replacement or maintenance, nylon mesh can be easily cleaned with water or a mild detergent, ensuring that it remains in optimal condition for years to come. This can help reduce downtime and maintenance costs, making 500 micron nylon mesh a smart investment for businesses looking to improve efficiency and productivity.

In conclusion, 500 micron nylon mesh is the best choice for heavy-duty applications due to its exceptional strength, filtration properties, versatility, and ease of maintenance. Whether you are filtering water, chemicals, or other substances, this durable and reliable material can help ensure that your end product meets the highest standards of quality and purity. If you are looking for a cost-effective solution that can withstand the demands of even the most challenging environments, consider using 500 micron nylon mesh for your next project.

How to Properly Maintain and Clean 500 Micron Nylon Mesh

When it comes to heavy-duty applications that require filtration, 500 micron nylon mesh is often the material of choice. This durable and versatile material is capable of handling high flow rates and can withstand the rigors of demanding environments. However, in order to ensure optimal performance and longevity, proper maintenance and cleaning of the nylon mesh is essential.

One of the most important aspects of maintaining 500 micron nylon mesh is regular inspection. By routinely checking the mesh for any signs of damage or wear, you can identify potential issues before they escalate. Look for tears, holes, or fraying along the edges of the mesh, as these can compromise its effectiveness. If any damage is found, it is important to address it promptly to prevent further deterioration.

In addition to visual inspection, it is also recommended to periodically test the flow rate of the nylon mesh. Over time, debris and contaminants can accumulate on the surface of the mesh, reducing its ability to effectively filter particles. By measuring the flow rate before and after cleaning, you can determine if the mesh is performing at its optimal level. If a significant decrease in flow rate is observed, it may be time to clean or replace the nylon mesh.

When it comes to cleaning 500 micron nylon mesh, there are several methods that can be used. One common approach is to rinse the mesh with water to remove any surface debris. For more stubborn contaminants, a mild detergent or cleaning solution can be applied to help break down buildup. It is important to avoid using harsh chemicals or abrasive cleaners, as these can damage the nylon mesh and reduce its effectiveness.

For more thorough cleaning, the nylon mesh can be soaked in a solution of warm water and mild detergent. Allow the mesh to soak for a few hours, then gently scrub with a soft brush to remove any remaining debris. Rinse the mesh thoroughly with clean water to remove any soap residue, then allow it to air dry completely before reinstalling.

In addition to regular cleaning, it is also important to properly store 500 micron nylon mesh when not in use. Store the mesh in a dry, cool environment away from direct sunlight to prevent degradation. Avoid folding or creasing the mesh, as this can cause permanent damage. If storing the mesh for an extended period of time, consider placing it in a protective case or container to prevent dust and debris from accumulating.

By following these maintenance and cleaning tips, you can ensure that your 500 micron nylon mesh remains in optimal condition for years to come. Proper care and attention to detail will not only extend the life of the mesh, but also ensure that it continues to perform at its best. With regular inspection, cleaning, and storage, you can maximize the efficiency and effectiveness of your nylon mesh in heavy-duty applications.

Comparing 500 Micron Nylon Mesh to Other Mesh Materials for Heavy-Duty Applications

When it comes to heavy-duty applications that require a durable and reliable mesh material, 500 micron nylon mesh stands out as one of the best choices available on the market. This versatile material offers a range of benefits that make it ideal for a wide variety of applications, from industrial filtration to screen printing and beyond.

One of the key advantages of 500 micron nylon mesh is its exceptional strength and durability. Nylon is known for its high tensile strength, making it capable of withstanding heavy loads and high pressures without tearing or breaking. This makes it an excellent choice for applications where the mesh will be subjected to significant stress or wear and tear.

In addition to its strength, 500 micron nylon mesh is also highly resistant to abrasion and chemicals. This makes it ideal for use in harsh environments where other materials may degrade or fail over time. Whether it’s exposure to corrosive chemicals, extreme temperatures, or rough handling, nylon mesh can hold up under the toughest conditions.

Another key advantage of 500 micron nylon mesh is its flexibility and versatility. Nylon mesh can be easily molded and shaped to fit a wide range of applications, making it suitable for everything from industrial filtration to screen printing and beyond. Its flexibility also allows for easy installation and maintenance, saving time and effort in the long run.

When compared to other mesh materials, such as stainless steel or polyester, 500 micron nylon mesh offers several distinct advantages. Stainless steel mesh, while strong and durable, can be heavy and difficult to work with. Polyester mesh, on the other hand, may not offer the same level of strength and durability as nylon.

In terms of cost, 500 micron nylon mesh is also a cost-effective option for heavy-duty applications. While it may be slightly more expensive than some other materials, the long-term durability and reliability of nylon mesh make it a wise investment for businesses looking to save money in the long run.

In conclusion, 500 micron nylon mesh is the best choice for heavy-duty applications that require a durable and reliable mesh material. Its exceptional strength, durability, resistance to abrasion and chemicals, flexibility, and cost-effectiveness make it a versatile option for a wide range of applications. Whether you’re in need of industrial filtration, screen printing, or any other heavy-duty application, nylon mesh is sure to meet your needs and exceed your expectations.