Table of Contents

Benefits of Using 50 micron stainless steel mesh for Industrial Applications

When it comes to industrial applications that require filtration, separation, or sieving, using the right type of mesh is crucial. One popular choice for many industries is 50 micron stainless steel mesh. This type of mesh offers a range of benefits that make it ideal for a variety of applications.

One of the key advantages of 50 micron stainless steel mesh is its durability. Stainless steel is known for its strength and resilience, making it a reliable material for industrial use. The 50 micron size of the mesh provides a fine filtration capability while still maintaining the strength and durability of stainless steel. This means that the mesh can withstand high temperatures, harsh chemicals, and heavy loads without losing its integrity.

In addition to its durability, 50 micron stainless steel mesh is also highly corrosion-resistant. This is a critical feature for industries that work with corrosive materials or in environments where rust and corrosion are common concerns. The stainless steel material used in this mesh is resistant to rust and corrosion, ensuring that it will maintain its effectiveness and longevity even in challenging conditions.

Another benefit of using 50 micron stainless steel mesh is its versatility. This type of mesh can be used in a wide range of applications, from food processing and pharmaceuticals to oil and gas production and wastewater treatment. Its fine filtration capability makes it suitable for separating particles of various sizes, while its durability and corrosion resistance make it ideal for use in demanding industrial environments.

Furthermore, 50 micron stainless steel mesh is easy to clean and maintain. Its smooth surface allows for easy removal of trapped particles, making it simple to keep the mesh clean and free from blockages. This not only helps to maintain the efficiency of the mesh but also prolongs its lifespan, reducing the need for frequent replacements.

In terms of cost-effectiveness, 50 micron stainless steel mesh offers a good return on investment. While the initial cost of stainless steel mesh may be higher than other materials, its durability and longevity mean that it will last longer and require less frequent replacement. This can result in cost savings over time, making stainless steel mesh a cost-effective choice for many industrial applications.

Overall, 50 micron stainless steel mesh is a durable, corrosion-resistant, versatile, and cost-effective option for a wide range of industrial applications. Its fine filtration capability, combined with its strength and resilience, make it an ideal choice for industries that require reliable and efficient filtration, separation, or sieving. Whether used in food processing, pharmaceuticals, oil and gas production, or wastewater treatment, 50 micron stainless steel mesh is sure to deliver exceptional performance and longevity.

How 50 Micron Stainless Steel Mesh Can Enhance Filtration Efficiency

When it comes to filtration systems, the quality of the mesh used plays a crucial role in determining the efficiency and effectiveness of the filtration process. One type of mesh that has gained popularity in recent years is the 50 micron stainless steel mesh. Known for its durability and corrosion-resistant properties, this type of mesh is widely used in various industries for a wide range of applications.

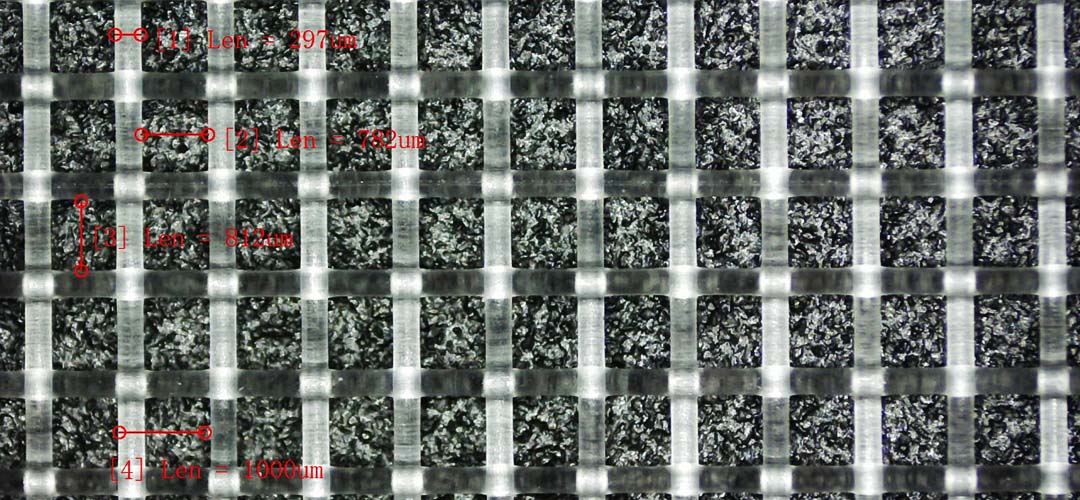

Stainless steel is a popular choice for mesh material due to its high strength, durability, and resistance to corrosion. The 50 micron size refers to the size of the openings in the mesh, with each opening measuring 50 microns in diameter. This size is ideal for filtering out fine particles and contaminants, making it suitable for applications where high precision filtration is required.

One of the key advantages of using 50 micron stainless steel mesh is its durability. Stainless steel is known for its strength and resilience, making it ideal for applications where the mesh is subjected to high pressure or abrasive materials. This durability ensures that the mesh can withstand harsh conditions without losing its effectiveness, making it a cost-effective choice for long-term use.

In addition to its durability, stainless steel mesh is also highly resistant to corrosion. This is particularly important in applications where the mesh comes into contact with corrosive substances or environments. The corrosion-resistant properties of stainless steel ensure that the mesh remains intact and functional even in challenging conditions, making it a reliable choice for a wide range of filtration applications.

The 50 micron size of the mesh openings is another key factor that contributes to its efficiency. The small size of the openings allows the mesh to filter out fine particles and contaminants that may be missed by larger mesh sizes. This level of precision filtration is essential in industries such as pharmaceuticals, food and beverage, and electronics, where even the smallest impurities can have a significant impact on product quality.

Furthermore, the 50 micron stainless steel mesh is easy to clean and maintain, making it a practical choice for applications that require regular maintenance. The smooth surface of stainless steel makes it easy to remove trapped particles and contaminants, ensuring that the mesh remains clean and free from blockages. This ease of maintenance helps to prolong the lifespan of the mesh and ensures consistent filtration performance over time.

In conclusion, 50 micron stainless steel mesh is a durable and corrosion-resistant material that can enhance filtration efficiency in a wide range of applications. Its strength, resilience, and precision filtration capabilities make it a reliable choice for industries that require high-quality filtration systems. Whether used in pharmaceuticals, food and beverage, electronics, or other industries, stainless steel mesh offers a cost-effective solution for achieving optimal filtration results. With its long-lasting performance and ease of maintenance, 50 micron stainless steel mesh is a valuable asset for any filtration system.

Maintenance Tips for Ensuring Longevity of 50 Micron Stainless Steel Mesh

When it comes to industrial filtration, 50 micron stainless steel mesh is a popular choice due to its durability and corrosion resistance. This type of mesh is commonly used in various applications, including oil and gas, food and beverage, pharmaceuticals, and water treatment. However, like any other equipment, proper maintenance is essential to ensure the longevity and efficiency of the mesh.

One of the key maintenance tips for 50 micron stainless steel mesh is regular cleaning. Over time, the mesh can become clogged with dirt, debris, and other contaminants, which can reduce its effectiveness. To prevent this, it is important to clean the mesh regularly using a mild detergent and water. Avoid using harsh chemicals or abrasive materials, as these can damage the mesh and reduce its lifespan.

In addition to regular cleaning, it is also important to inspect the mesh for any signs of damage or wear. Check for tears, holes, or corrosion, as these can compromise the integrity of the mesh and affect its performance. If any damage is found, it is important to repair or replace the mesh as soon as possible to prevent further issues.

Another important maintenance tip for 50 micron stainless steel mesh is proper storage. When not in use, the mesh should be stored in a clean, dry environment to prevent rust and corrosion. Avoid storing the mesh in humid or damp conditions, as this can accelerate corrosion and reduce the lifespan of the mesh. Additionally, it is important to store the mesh away from any sharp objects or abrasive materials that could cause damage.

Regular inspection and maintenance of 50 micron stainless steel mesh are essential to ensure its longevity and efficiency. By following these maintenance tips, you can extend the lifespan of the mesh and ensure that it continues to perform at its best. Remember to clean the mesh regularly, inspect it for damage, and store it properly to prevent corrosion and other issues.

In conclusion, 50 micron stainless steel mesh is a durable and corrosion-resistant material that is commonly used in industrial filtration applications. Proper maintenance is essential to ensure the longevity and efficiency of the mesh. By following the maintenance tips outlined in this article, you can keep your mesh in top condition and maximize its performance. Remember to clean the mesh regularly, inspect it for damage, and store it properly to prevent corrosion and other issues. With proper maintenance, your 50 micron stainless steel mesh will continue to provide reliable filtration for years to come.