Table of Contents

Benefits of Using 50 micron nylon mesh for Fine Filtration

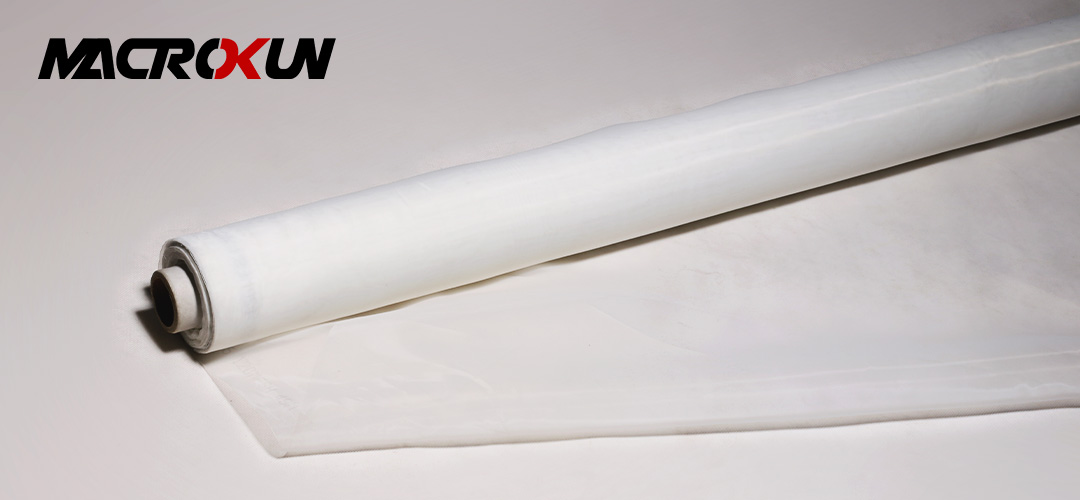

When it comes to fine filtration needs, having the right tools and materials is essential. One such material that has proven to be highly effective in achieving precise filtration is 50 micron nylon mesh. This finely crafted mesh is designed to capture even the smallest particles, making it ideal for a wide range of applications where precision is key.

One of the main benefits of using 50 micron nylon mesh is its ability to provide consistent and reliable filtration results. The uniformity of the mesh ensures that particles of a certain size are captured with precision, leaving behind only the desired material. This level of accuracy is crucial in industries such as pharmaceuticals, food and beverage, and electronics, where even the smallest impurities can have a significant impact on the final product.

In addition to its precision, 50 micron nylon mesh is also known for its durability and longevity. Made from high-quality nylon material, this mesh is designed to withstand harsh conditions and repeated use without losing its effectiveness. This means that businesses can rely on this mesh for their filtration needs for an extended period of time, saving both time and money in the long run.

Furthermore, 50 micron nylon mesh is easy to clean and maintain, making it a cost-effective solution for businesses looking to streamline their filtration processes. With regular cleaning and proper care, this mesh can continue to deliver optimal results, ensuring that operations run smoothly and efficiently.

Another key benefit of using 50 micron nylon mesh is its versatility. This mesh can be customized to meet specific filtration requirements, making it suitable for a wide range of applications. Whether filtering liquids, gases, or solids, this mesh can be tailored to achieve the desired level of filtration, making it a versatile and adaptable solution for businesses in various industries.

Moreover, 50 micron nylon mesh is environmentally friendly, making it a sustainable choice for businesses looking to reduce their carbon footprint. This mesh can be recycled and reused, minimizing waste and promoting a more eco-friendly approach to filtration. By choosing this mesh, businesses can not only improve their filtration processes but also contribute to a cleaner and greener environment.

In conclusion, 50 micron nylon mesh is a precision-crafted material that offers a wide range of benefits for businesses with fine filtration needs. From its accuracy and durability to its versatility and sustainability, this mesh is a reliable and cost-effective solution for achieving optimal filtration results. By investing in 50 micron nylon mesh, businesses can improve their operations, reduce costs, and contribute to a more sustainable future.

Applications of 50 Micron Nylon Mesh in Various Industries

50 Micron Nylon Mesh: Precision Crafted for Fine Filtration Needs

In the world of filtration, precision is key. Whether it’s removing impurities from liquids or separating particles in a manufacturing process, having the right filtration material can make all the difference. One such material that has gained popularity for its fine filtration capabilities is 50 micron nylon mesh. This finely crafted mesh is designed to capture even the smallest particles, making it ideal for a wide range of applications across various industries.

One of the primary industries that benefit from the use of 50 micron nylon mesh is the pharmaceutical industry. In pharmaceutical manufacturing, maintaining a high level of purity is essential to ensure the safety and efficacy of the final product. 50 micron nylon mesh is often used in filtration systems to remove contaminants and impurities from liquids and gases, helping to meet the stringent quality standards required in this industry.

Another industry that relies heavily on the precision of 50 micron nylon mesh is the food and beverage industry. From filtering out solids in juices and syrups to removing impurities in beer and wine production, this fine mesh plays a crucial role in ensuring the quality and purity of food and beverage products. With its ability to capture particles as small as 50 microns, nylon mesh helps to maintain the integrity of the final product, meeting the strict regulatory requirements of the industry.

In the automotive industry, 50 micron nylon mesh is used in a variety of applications, from filtering hydraulic fluids and lubricants to separating particles in paint and coating processes. The fine filtration capabilities of nylon mesh help to improve the performance and longevity of automotive components, ensuring that vehicles operate smoothly and efficiently. With its durability and resistance to chemicals and abrasion, nylon mesh is well-suited for the demanding conditions of the automotive industry.

The electronics industry also benefits from the precision of 50 micron nylon mesh. In electronic manufacturing, maintaining a clean and controlled environment is essential to prevent contamination and ensure the reliability of electronic components. Nylon mesh is used in filtration systems to remove dust, debris, and other particles that can compromise the quality of electronic products. With its fine filtration capabilities, nylon mesh helps to protect sensitive electronic components and ensure the integrity of the final product.

In the aerospace industry, where precision and reliability are paramount, 50 micron nylon mesh is used in a variety of applications, from filtering hydraulic fluids and lubricants to separating particles in fuel systems. Nylon mesh helps to ensure the safety and performance of aircraft components by capturing contaminants and impurities that can cause equipment failure. With its high strength-to-weight ratio and resistance to extreme temperatures, nylon mesh is well-suited for the demanding conditions of aerospace applications.

In conclusion, 50 micron nylon mesh is a precision-crafted material that is well-suited for fine filtration needs across a wide range of industries. From pharmaceuticals to food and beverage, automotive to electronics, and aerospace, nylon mesh plays a crucial role in ensuring the quality, purity, and reliability of products and processes. With its fine filtration capabilities, durability, and resistance to chemicals and abrasion, nylon mesh is a versatile and reliable solution for the most demanding filtration applications.

How to Properly Maintain and Clean 50 Micron Nylon Mesh Filters

When it comes to fine filtration needs, 50 micron nylon mesh filters are a popular choice for many industries. These precision-crafted filters are designed to capture even the smallest particles, making them ideal for applications where cleanliness and purity are essential. However, like any filter, proper maintenance and cleaning are crucial to ensure optimal performance and longevity.

One of the most important aspects of maintaining 50 micron nylon mesh filters is regular cleaning. Over time, particles and debris can build up on the surface of the filter, reducing its effectiveness and potentially causing damage. To prevent this, it is recommended to clean the filter regularly, depending on the level of contamination it is exposed to.

To clean a 50 micron nylon mesh filter, start by removing it from the filtration system and gently rinsing it with warm water. Avoid using harsh chemicals or abrasive cleaners, as these can damage the delicate mesh material. Instead, use a mild detergent or specialized filter cleaner to gently scrub away any buildup. Be sure to rinse the filter thoroughly to remove any soap residue before reinstalling it.

In addition to regular cleaning, it is also important to inspect the filter for any signs of damage or wear. Check for tears, holes, or other imperfections that could compromise the filter’s effectiveness. If any damage is found, it is best to replace the filter to ensure optimal filtration performance.

Another important aspect of maintaining 50 micron nylon mesh filters is proper storage. When not in use, filters should be stored in a clean, dry environment to prevent contamination and damage. Avoid storing filters in areas where they may be exposed to extreme temperatures or humidity, as this can degrade the material over time.

In addition to regular cleaning and proper storage, it is also important to monitor the performance of 50 micron nylon mesh filters over time. Keep track of how often the filter needs to be cleaned and replaced, as this can help identify any potential issues with the filtration system. If the filter is becoming clogged more frequently or if the quality of the filtration is decreasing, it may be time to replace the filter.

Overall, proper maintenance and cleaning are essential for ensuring the longevity and effectiveness of 50 micron nylon mesh filters. By following these guidelines and staying proactive in monitoring filter performance, you can ensure that your filtration system continues to operate at peak efficiency. Remember, a well-maintained filter is a key component of any successful filtration system.