Table of Contents

Applications of 50 micron nylon mesh in Water Filtration

50 Micron Nylon Mesh has emerged as a pivotal component in the realm of water filtration, offering a lightweight and efficient solution for various applications. Its unique properties make it particularly suitable for filtering out particulates while allowing for optimal water flow. This balance of performance and efficiency is crucial in industries where water quality is paramount, such as in municipal water treatment, aquaculture, and industrial processes. The mesh’s fine filtration capability ensures that contaminants, including sediments and larger microorganisms, are effectively removed, resulting in cleaner and safer water.

In municipal water treatment facilities, the use of 50 Micron Nylon Mesh is increasingly common. As water is sourced from rivers, lakes, or reservoirs, it often contains a variety of impurities. The nylon mesh acts as a first line of defense, capturing larger particles before they enter more complex filtration systems. This pre-filtration step not only enhances the overall efficiency of the treatment process but also prolongs the lifespan of subsequent filtration equipment. By reducing the load on these systems, municipalities can achieve significant cost savings while ensuring compliance with stringent water quality standards.

Aquaculture is another sector that benefits greatly from the application of 50 Micron Nylon Mesh. In fish farming, maintaining water quality is essential for the health and growth of aquatic species. The mesh is utilized in various filtration systems to remove uneaten feed, fish waste, and other organic matter that can compromise water quality. By ensuring that the water remains clean and well-oxygenated, aquaculture operations can enhance fish survival rates and promote faster growth, ultimately leading to increased productivity and profitability. The lightweight nature of nylon mesh also facilitates easy handling and installation, making it a preferred choice among aquaculture professionals.

Industrial processes often require specific water quality parameters to ensure optimal operation. In manufacturing settings, water is frequently used for cooling, cleaning, and as a solvent. The presence of contaminants can lead to equipment malfunctions and product quality issues. Here, 50 Micron Nylon Mesh serves as an effective filtration solution, capturing particles that could otherwise disrupt operations. Its durability and resistance to chemicals make it suitable for a wide range of industrial applications, from food processing to pharmaceuticals. By integrating nylon mesh into their water management systems, industries can maintain high standards of cleanliness and efficiency.

Moreover, the versatility of 50 Micron Nylon Mesh extends to residential applications as well. Homeowners increasingly seek effective filtration solutions to ensure the quality of their drinking water. The mesh can be incorporated into various filtration systems, including under-sink filters and whole-house systems, providing an additional layer of protection against contaminants. This not only enhances the safety of drinking water but also contributes to better-tasting water, which is a significant consideration for many consumers. As awareness of water quality issues grows, the demand for reliable filtration solutions like 50 Micron Nylon Mesh is expected to rise.

In conclusion, the applications of 50 Micron Nylon Mesh in water filtration are diverse and impactful. Its lightweight and efficient design make it an ideal choice for municipal water treatment, aquaculture, industrial processes, and residential filtration systems. As industries and consumers alike prioritize water quality, the role of nylon mesh in ensuring clean and safe water will continue to expand, solidifying its position as a vital component in modern filtration solutions. The ongoing advancements in filtration technology will likely further enhance the effectiveness of 50 Micron Nylon Mesh, making it an indispensable tool in the quest for cleaner water.

Benefits of Using 50 Micron Nylon Mesh for Industrial Filtration

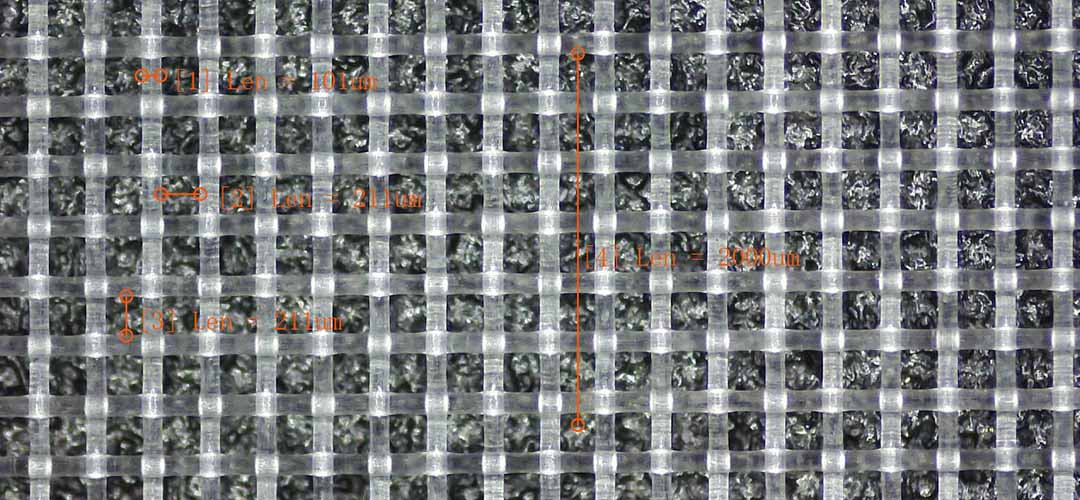

50 Micron Nylon Mesh has emerged as a pivotal component in industrial filtration processes, offering a range of benefits that enhance efficiency and effectiveness. One of the primary advantages of using this specific mesh size is its ability to strike a balance between filtration precision and flow rate. With a pore size of 50 microns, it effectively captures particles while allowing liquids to pass through with minimal resistance. This characteristic is particularly beneficial in applications where maintaining a high flow rate is essential, such as in water treatment facilities and chemical processing plants.

Moreover, the lightweight nature of nylon mesh contributes significantly to its usability in various industrial settings. Unlike heavier filtration materials, 50 Micron Nylon Mesh is easy to handle and install, reducing labor costs and time associated with setup. This ease of use does not compromise its durability; in fact, nylon is known for its resilience against wear and tear, making it a long-lasting solution for filtration needs. The mesh can withstand a range of temperatures and chemical exposures, which is crucial in industries that deal with aggressive substances.

Another notable benefit is the mesh’s resistance to clogging. In many filtration systems, clogging can lead to increased downtime and maintenance costs. However, the design of 50 Micron Nylon Mesh minimizes this issue, allowing for continuous operation without frequent interruptions for cleaning or replacement. This efficiency not only enhances productivity but also contributes to a more sustainable operation by reducing waste associated with discarded filters.

In addition to its practical advantages, 50 Micron Nylon Mesh also supports compliance with industry standards. Many sectors, including food and beverage, pharmaceuticals, and environmental services, require stringent filtration processes to ensure product safety and quality. The consistent performance of nylon mesh in filtering out contaminants helps businesses meet these regulatory requirements, thereby avoiding potential fines and enhancing their reputation in the market.

Furthermore, the versatility of 50 Micron Nylon Mesh cannot be overlooked. It can be utilized in various applications, from liquid filtration to air filtration systems. This adaptability makes it an ideal choice for companies looking to streamline their operations by using a single type of filtration material across multiple processes. By standardizing on 50 Micron Nylon Mesh, businesses can simplify inventory management and reduce costs associated with sourcing different materials for different applications.

Cost-effectiveness is another critical factor driving the adoption of 50 Micron Nylon Mesh in industrial filtration. While the initial investment may be comparable to other filtration options, the long-term savings realized through reduced maintenance, lower replacement rates, and improved operational efficiency make it a financially sound choice. Companies can allocate resources more effectively, focusing on core operations rather than dealing with frequent filtration issues.

In conclusion, the benefits of using 50 Micron Nylon Mesh for industrial filtration are manifold. Its lightweight and durable nature, combined with resistance to clogging and compliance with industry standards, positions it as a superior choice for various applications. The versatility and cost-effectiveness further enhance its appeal, making it an essential component in modern filtration systems. As industries continue to seek efficient and reliable solutions, 50 Micron Nylon Mesh stands out as a key player in achieving optimal filtration performance.

Comparing 50 Micron Nylon Mesh with Other Filtration Materials

When it comes to filtration solutions, choosing the right material is crucial to ensure optimal performance. One material that has gained popularity in recent years is 50 micron nylon mesh. This lightweight and efficient material offers a range of benefits that make it a top choice for many industries. In this article, we will compare 50 micron nylon mesh with other filtration materials to highlight its advantages and why it is a superior option for your filtration needs.

One of the key advantages of 50 micron nylon mesh is its durability. Unlike some other filtration materials that can break or tear easily, nylon mesh is known for its strength and resilience. This means that it can withstand high pressures and temperatures without compromising its filtration capabilities. In addition, nylon mesh is resistant to chemicals and abrasion, making it a versatile option for a wide range of applications.

Another benefit of 50 micron nylon mesh is its efficiency. The small pore size of 50 microns allows for the filtration of fine particles and contaminants, ensuring that your end product is clean and pure. This level of filtration is essential in industries such as pharmaceuticals, food and beverage, and electronics, where even the smallest impurities can have a significant impact on product quality.

In comparison to other filtration materials, such as stainless steel or polyester, 50 micron nylon mesh offers a higher flow rate. This means that it can process more liquid or gas in a shorter amount of time, increasing productivity and efficiency. Additionally, nylon mesh is lightweight and easy to handle, making it a cost-effective option for filtration systems that require frequent maintenance or replacement.

One of the main advantages of 50 micron nylon mesh is its affordability. Compared to other filtration materials, such as ceramic or glass fiber, nylon mesh is a more budget-friendly option that does not compromise on quality. This makes it an attractive choice for businesses looking to reduce costs without sacrificing performance.

In terms of maintenance, 50 micron nylon mesh is easy to clean and reuse, reducing the need for frequent replacements. This not only saves time and money but also minimizes waste and environmental impact. Additionally, nylon mesh can be customized to meet specific filtration requirements, making it a versatile option for a variety of industries.

Overall, 50 micron nylon mesh stands out as a superior filtration material due to its durability, efficiency, affordability, and ease of maintenance. Whether you are in the pharmaceutical, food and beverage, or electronics industry, nylon mesh offers a reliable and cost-effective solution for your filtration needs. By choosing 50 micron nylon mesh, you can ensure that your products meet the highest standards of quality and purity, giving you a competitive edge in the market.