Table of Contents

Benefits of Using 400 micron mesh for Coarse Filtration

The use of 400 micron mesh for coarse filtration presents a multitude of benefits that cater to various industrial and commercial applications. One of the primary advantages of this mesh size is its ability to effectively separate larger particles from liquids or gases, ensuring that the filtration process is both efficient and reliable. This capability is particularly crucial in industries such as food and beverage, pharmaceuticals, and water treatment, where maintaining product purity and quality is paramount. By utilizing a 400 micron mesh, businesses can significantly reduce the risk of contamination, thereby enhancing the overall safety and integrity of their products.

Moreover, the durability of 400 micron mesh contributes to its appeal in coarse filtration applications. Constructed from robust materials such as stainless steel or high-density polyethylene, this mesh can withstand harsh operating conditions, including high temperatures and corrosive environments. This resilience not only extends the lifespan of the filtration system but also minimizes maintenance costs, allowing companies to allocate resources more effectively. As a result, organizations can focus on their core operations without the constant worry of equipment failure or the need for frequent replacements.

In addition to its strength, the 400 micron mesh offers versatility in various filtration processes. It can be employed in a range of settings, from industrial manufacturing to environmental applications, making it a valuable asset for businesses looking to streamline their operations. For instance, in the agricultural sector, this mesh can be used to filter irrigation water, ensuring that plants receive clean water free from harmful debris. Similarly, in the mining industry, it can assist in the separation of minerals from slurry, enhancing the efficiency of mineral recovery processes. This adaptability underscores the mesh’s role as a fundamental component in diverse filtration systems.

Another significant benefit of using 400 micron mesh is its cost-effectiveness. While initial investments in filtration systems can be substantial, the long-term savings associated with reduced maintenance and increased operational efficiency often outweigh these costs. By preventing the passage of larger particles, the mesh helps to protect downstream equipment, such as pumps and valves, from wear and tear. This protection not only prolongs the life of these components but also reduces the likelihood of costly downtime, which can have a detrimental impact on productivity and profitability.

Furthermore, the ease of installation and replacement of 400 micron mesh makes it an attractive option for businesses seeking to optimize their filtration processes. Many filtration systems are designed to accommodate standard mesh sizes, allowing for quick and straightforward upgrades. This simplicity ensures that companies can implement improvements without extensive downtime or disruption to their operations. As industries continue to evolve and demand higher standards of filtration, the ability to adapt quickly becomes a critical factor in maintaining a competitive edge.

In conclusion, the benefits of using 400 micron mesh for coarse filtration are manifold, encompassing enhanced efficiency, durability, versatility, cost-effectiveness, and ease of use. As businesses strive to meet stringent quality standards and improve operational performance, the adoption of robust filtration solutions like 400 micron mesh becomes increasingly essential. By investing in this reliable filtration technology, organizations can not only safeguard their products but also position themselves for sustained success in an ever-changing marketplace.

How to Choose the Right 400 Micron Mesh for Your Filtration Needs

When it comes to selecting the appropriate 400 micron mesh for your filtration needs, understanding the specific requirements of your application is paramount. The choice of mesh can significantly impact the efficiency and effectiveness of the filtration process, making it essential to consider various factors before making a decision. First and foremost, it is crucial to assess the type of material you will be filtering. Different materials, whether they are liquids or solids, have unique properties that can influence the performance of the mesh. For instance, if you are dealing with a viscous liquid, a mesh that allows for adequate flow while still capturing larger particles is necessary. Conversely, if you are filtering out larger solids from a slurry, the mesh must be robust enough to withstand the pressure and prevent clogging.

In addition to the material being filtered, the operating environment plays a significant role in mesh selection. Factors such as temperature, pressure, and chemical compatibility must be taken into account. For example, if the filtration process occurs in a high-temperature environment, it is essential to choose a mesh that can withstand such conditions without degrading. Similarly, if the materials being filtered are corrosive, selecting a mesh made from resistant materials, such as stainless steel or specialized polymers, will ensure longevity and reliability. Furthermore, understanding the flow rate requirements of your application is critical. A 400 micron mesh can provide a balance between filtration efficiency and flow rate, but it is essential to ensure that the chosen mesh can accommodate the desired throughput without compromising performance.

Another important consideration is the mesh’s construction and design. Different weaving techniques can affect the mesh’s strength and flexibility, which in turn influences its performance in various applications. For instance, a plain weave may offer a different level of durability compared to a twill weave. Additionally, the mesh’s opening shape can also impact its filtration capabilities. Therefore, it is advisable to consult with manufacturers or suppliers who can provide insights into the best mesh design for your specific needs. Moreover, it is beneficial to consider the ease of maintenance and cleaning when selecting a 400 micron mesh. Some applications may require frequent cleaning to maintain optimal performance, so choosing a mesh that is easy to disassemble and clean can save time and resources in the long run.

Cost is another factor that cannot be overlooked. While it may be tempting to opt for the least expensive option, it is essential to evaluate the long-term value of the mesh. Investing in a high-quality 400 micron mesh may result in lower maintenance costs and improved filtration efficiency, ultimately leading to cost savings over time. Therefore, it is wise to weigh the initial investment against the potential benefits. Lastly, seeking expert advice can be invaluable in the decision-making process. Engaging with filtration specialists or industry professionals can provide insights that may not be immediately apparent. They can help you navigate the complexities of mesh selection and ensure that you choose the right product for your specific filtration needs.

In conclusion, selecting the right 400 micron mesh for your filtration needs involves a careful assessment of various factors, including the material being filtered, the operating environment, flow rate requirements, mesh construction, maintenance considerations, cost, and expert advice. By taking the time to evaluate these elements, you can ensure that your filtration system operates efficiently and effectively, ultimately leading to better outcomes for your business.

Case Studies Highlighting the Effectiveness of 400 Micron Mesh in Various Industries

In the world of filtration, finding the right solution for your specific needs is crucial. Whether you are dealing with wastewater treatment, food processing, or any other industry that requires filtration, having the right equipment can make all the difference. One such solution that has been gaining popularity in recent years is the use of 400 micron mesh for coarse filtration.

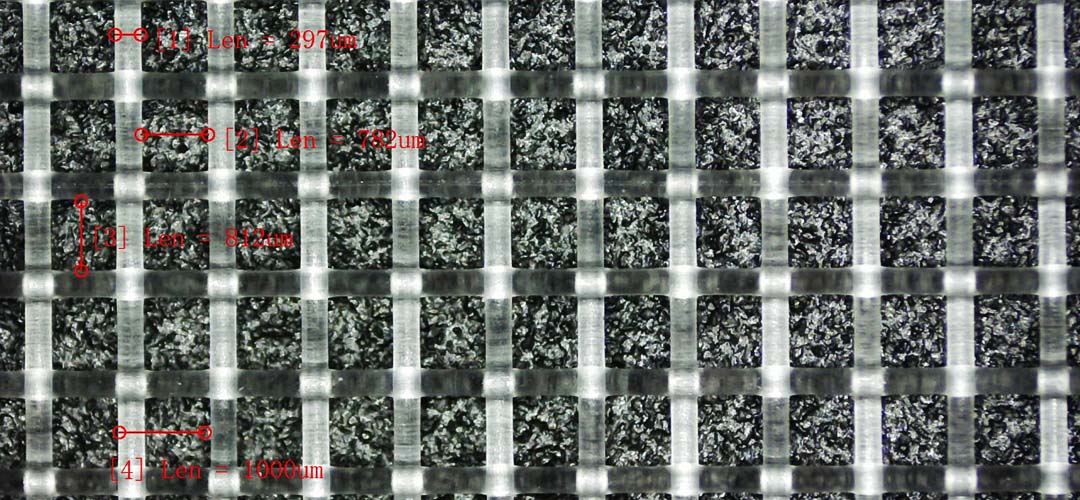

400 micron mesh is a versatile and robust material that is capable of capturing particles as small as 0.016 inches in diameter. This makes it an ideal choice for applications where larger particles need to be removed from a liquid or gas stream. In this article, we will explore some case studies that highlight the effectiveness of 400 micron mesh in various industries.

One industry that has seen great success with the use of 400 micron mesh is the wastewater treatment sector. In a recent case study, a wastewater treatment plant in a major city was struggling with high levels of suspended solids in their effluent. These solids were causing issues with downstream processes and were also impacting the quality of the treated water.

By implementing a 400 micron mesh filtration system, the plant was able to effectively remove the suspended solids from the effluent, resulting in a significant improvement in water quality. The plant saw a reduction in maintenance costs, as well as an increase in overall efficiency. The use of 400 micron mesh proved to be a cost-effective and reliable solution for their coarse filtration needs.

Another industry that has benefited from the use of 400 micron mesh is the food processing industry. In a case study conducted at a large food processing plant, the company was facing challenges with removing large particles from their product stream. These particles were causing issues with product quality and were also leading to increased downtime due to equipment failures.

By incorporating a 400 micron mesh filtration system into their process, the plant was able to effectively remove the large particles from their product stream, resulting in a significant improvement in product quality. The plant also saw a reduction in equipment failures and maintenance costs, as well as an increase in overall productivity. The use of 400 micron mesh proved to be a reliable and efficient solution for their coarse filtration needs.

In conclusion, the use of 400 micron mesh for coarse filtration has proven to be a valuable solution for a wide range of industries. From wastewater treatment to food processing, this versatile material has shown its effectiveness in capturing large particles and improving overall process efficiency. By incorporating 400 micron mesh into their filtration systems, companies can achieve cost savings, improved product quality, and increased productivity. If you are looking for a robust solution for your coarse filtration needs, consider the benefits of 400 micron mesh.