Table of Contents

Benefits of Using 200 Micron Filter Mesh in Industrial Applications

When it comes to industrial filtration, finding the right balance between filtration efficiency and durability is crucial. One popular option that strikes this balance is the 200 micron filter mesh. This type of filter mesh offers a range of benefits that make it ideal for a variety of industrial applications.

One of the key advantages of using a 200 micron filter mesh is its filtration efficiency. With a mesh size of 200 microns, this type of filter is capable of capturing particles as small as 0.0079 inches. This level of filtration is essential for industries that require high levels of cleanliness and purity in their processes, such as pharmaceuticals, food and beverage, and electronics manufacturing.

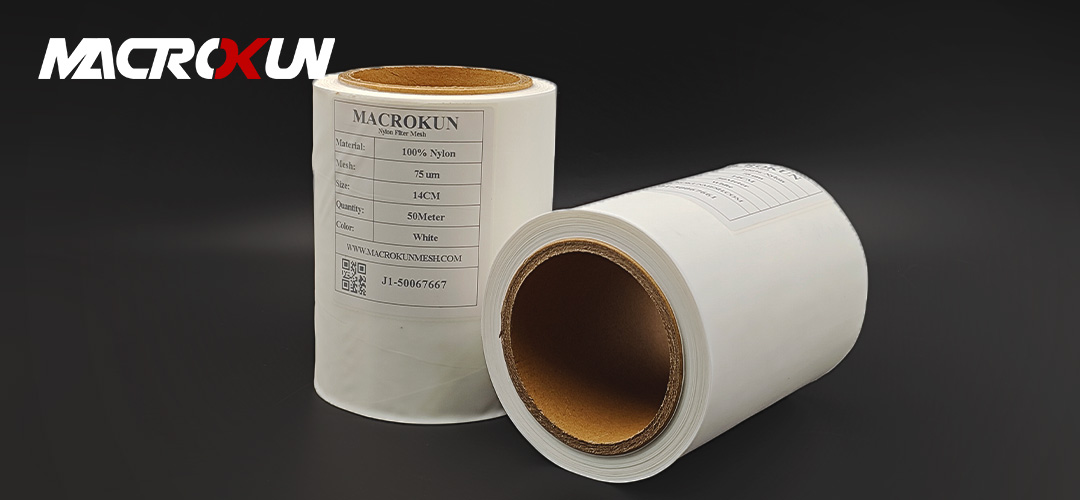

In addition to its filtration efficiency, 200 micron filter mesh is also known for its durability. Made from high-quality materials such as stainless steel or nylon, this type of filter mesh is designed to withstand harsh operating conditions and frequent use. This durability ensures that the filter mesh will last longer and require less frequent replacement, saving time and money in the long run.

Another benefit of using 200 micron filter mesh is its versatility. This type of filter mesh can be used in a wide range of industrial applications, from water and wastewater treatment to oil and gas refining. Its ability to effectively capture particles of various sizes makes it a versatile option for industries with diverse filtration needs.

Furthermore, 200 micron filter mesh is easy to clean and maintain, making it a cost-effective choice for industrial filtration systems. Regular cleaning and maintenance of the filter mesh can help prolong its lifespan and ensure optimal performance. This ease of maintenance is especially important for industries that rely on continuous filtration to maintain their processes.

In conclusion, the benefits of using 200 micron filter mesh in industrial applications are clear. Its combination of filtration efficiency, durability, versatility, and ease of maintenance make it an ideal choice for industries that require high-quality filtration. Whether you are in the pharmaceutical, food and beverage, or electronics manufacturing industry, investing in a 200 micron filter mesh can help improve the efficiency and effectiveness of your filtration processes.

How to Choose the Right 200 Micron Filter Mesh for Your Needs

When it comes to choosing the right filter mesh for your needs, there are a few key factors to consider. One of the most important considerations is the micron size of the mesh. A 200 micron filter mesh is a popular choice for many applications due to its balance of filtration efficiency and durability.

The micron size of a filter mesh refers to the size of the openings in the mesh. A 200 micron filter mesh has openings that are 200 microns in size, which is small enough to capture most particles and debris while still allowing for adequate flow through the mesh. This makes it an ideal choice for applications where a high level of filtration is required, such as in water treatment systems or industrial processes.

One of the key benefits of a 200 micron filter mesh is its filtration efficiency. The small size of the openings in the mesh allows it to capture even tiny particles, ensuring that the filtered liquid or gas is free of contaminants. This can help to improve the quality of the end product and prevent damage to equipment or machinery.

In addition to its filtration efficiency, a 200 micron filter mesh is also known for its durability. The mesh is typically made from high-quality materials such as stainless steel or nylon, which are resistant to corrosion and wear. This means that the mesh can withstand harsh conditions and heavy use without becoming damaged or clogged, ensuring that it remains effective over time.

When choosing a 200 micron filter mesh, it is important to consider the specific requirements of your application. For example, if you are filtering a liquid with a high concentration of particles, you may need a mesh with a smaller micron size to ensure thorough filtration. On the other hand, if you are filtering a less contaminated liquid, a 200 micron mesh may be sufficient.

It is also important to consider the material of the mesh when choosing a 200 micron filter. Stainless steel mesh is a popular choice due to its strength and resistance to corrosion, making it ideal for use in industrial applications. nylon mesh, on the other hand, is lightweight and flexible, making it a good choice for applications where ease of handling is important.

In conclusion, a 200 micron filter mesh is a versatile and effective choice for a wide range of applications. Its balance of filtration efficiency and durability makes it a popular choice for industries such as water treatment, food and beverage, and pharmaceuticals. By considering the specific requirements of your application and choosing a high-quality mesh material, you can ensure that your filtration system operates efficiently and effectively for years to come.

Maintenance Tips for Extending the Lifespan of Your 200 Micron Filter Mesh

When it comes to maintaining the efficiency and longevity of your 200 micron filter mesh, there are several key tips to keep in mind. This type of filter mesh is commonly used in a variety of industries, including water treatment, food processing, and pharmaceuticals, due to its ability to effectively capture small particles while still allowing for adequate flow rates. However, in order to ensure that your filter mesh continues to perform at its best, it is important to take proper care of it.

One of the most important maintenance tips for extending the lifespan of your 200 micron filter mesh is to regularly clean and inspect it. Over time, debris and particles can build up on the surface of the mesh, reducing its effectiveness and potentially causing damage. By regularly cleaning the filter mesh with a gentle detergent and water, you can help to prevent clogs and ensure that it continues to function properly.

In addition to cleaning the filter mesh, it is also important to inspect it regularly for any signs of wear or damage. Look for tears, holes, or other imperfections that could compromise the integrity of the mesh. If you notice any issues, it is important to address them promptly in order to prevent further damage and ensure that your filter mesh continues to perform effectively.

Another key maintenance tip for extending the lifespan of your 200 micron filter mesh is to avoid exposing it to harsh chemicals or extreme temperatures. Chemicals can degrade the material of the mesh, while extreme temperatures can cause it to warp or become brittle. By storing your filter mesh in a cool, dry place and avoiding contact with harsh chemicals, you can help to prolong its lifespan and ensure that it continues to function effectively.

Finally, it is important to replace your 200 micron filter mesh on a regular basis. Over time, the mesh can become worn out and less effective at capturing particles. By replacing it at regular intervals, you can ensure that your filtration system continues to operate at its best and prevent any potential issues from arising.

In conclusion, maintaining your 200 micron filter mesh is essential for ensuring that it continues to perform at its best. By regularly cleaning and inspecting the mesh, avoiding exposure to harsh chemicals and extreme temperatures, and replacing it on a regular basis, you can help to extend its lifespan and keep your filtration system running smoothly. By following these maintenance tips, you can strike a balance between filtration efficiency and durability, ensuring that your 200 micron filter mesh continues to meet your needs for years to come.