Table of Contents

Benefits of Using 120 Micron Screens for Efficient Filtration

When it comes to filtration, choosing the right screen size is crucial to achieving efficient and effective results. 120 micron screens are a popular choice for filtering medium-sized particles in various industries due to their reliability and versatility. These screens offer a balance between capturing smaller particles while allowing larger particles to pass through, making them ideal for a wide range of applications.

One of the key benefits of using 120 micron screens is their ability to provide consistent and reliable filtration. The uniformity of the screen openings ensures that particles of the desired size are captured while allowing smaller particles to pass through. This level of precision is essential for industries that require consistent filtration results to maintain product quality and meet regulatory standards.

In addition to their reliability, 120 micron screens are also highly versatile. They can be used in a variety of filtration systems, including pressure filters, vacuum filters, and gravity filters. This versatility makes them suitable for a wide range of applications, from wastewater treatment to food and beverage processing.

Another advantage of using 120 micron screens is their durability. These screens are typically made from high-quality materials such as stainless steel or polypropylene, which are resistant to corrosion and wear. This durability ensures that the screens can withstand harsh operating conditions and continue to provide effective filtration over an extended period of time.

Furthermore, 120 micron screens are easy to clean and maintain, reducing downtime and maintenance costs. Regular cleaning and maintenance of the screens can help prolong their lifespan and ensure optimal filtration performance. This ease of maintenance is particularly beneficial for industries that require frequent screen cleaning to prevent clogging and maintain filtration efficiency.

In addition to their reliability, versatility, and durability, 120 micron screens also offer cost-effective filtration solutions. These screens are available in a range of sizes and configurations to suit different filtration requirements, making them a cost-effective option for businesses of all sizes. By investing in 120 micron screens, businesses can achieve efficient filtration results without breaking the bank.

Overall, 120 micron screens are a reliable and versatile filtration solution for capturing medium-sized particles in various industries. Their precision, durability, ease of maintenance, and cost-effectiveness make them a popular choice for businesses looking to achieve efficient filtration results. Whether you are in the wastewater treatment, food and beverage, or pharmaceutical industry, 120 micron screens can help you achieve optimal filtration performance and maintain product quality. Consider incorporating 120 micron screens into your filtration system to experience the benefits of reliable and efficient filtration for medium-sized particles.

How 120 Micron Screens Improve Filtration of Medium-Sized Particles

When it comes to filtration, choosing the right screen size is crucial to achieving optimal results. For medium-sized particles, a 120 micron screen is often the ideal choice. These screens offer reliable filtration that effectively captures particles of a specific size range, ensuring that only the desired particles pass through while larger contaminants are removed. In this article, we will explore how 120 micron screens improve the filtration of medium-sized particles and why they are a popular choice in various industries.

One of the key benefits of using a 120 micron screen for filtration is its ability to effectively capture particles that fall within the medium size range. These screens are designed to allow particles that are smaller than 120 microns to pass through while trapping larger particles. This makes them ideal for applications where a specific particle size needs to be removed from a liquid or gas stream. By using a 120 micron screen, you can ensure that only particles of a certain size are allowed to flow through, resulting in a cleaner and more refined end product.

In addition to their precise filtration capabilities, 120 micron screens are also known for their durability and reliability. These screens are typically made from high-quality materials that can withstand the rigors of industrial use. Whether you are filtering water, chemicals, or other substances, a 120 micron screen can provide long-lasting performance and consistent results. This reliability is essential in industries where filtration is critical to maintaining product quality and ensuring regulatory compliance.

Another advantage of using 120 micron screens is their versatility. These screens can be used in a wide range of applications, from food and beverage processing to pharmaceutical manufacturing. Whether you are removing impurities from a liquid product or separating particles from a gas stream, a 120 micron screen can deliver the filtration performance you need. This versatility makes 120 micron screens a popular choice among industries that require precise and efficient filtration solutions.

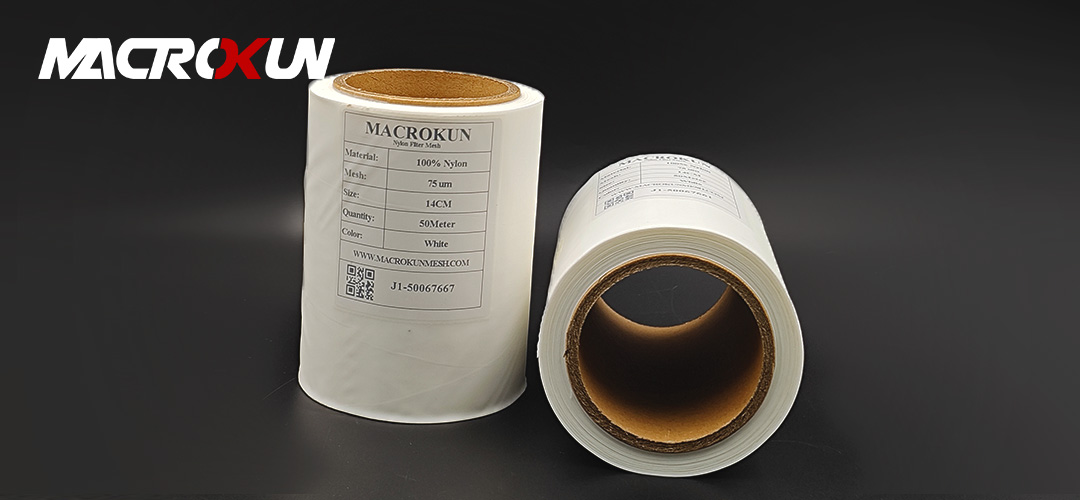

When it comes to selecting a 120 micron screen for your filtration needs, there are a few factors to consider. The material of the screen is one of the most important considerations, as different materials offer varying levels of durability and chemical resistance. Stainless steel screens are a popular choice for their strength and corrosion resistance, while nylon screens are preferred for their flexibility and ease of cleaning. By choosing the right material for your application, you can ensure that your 120 micron screen will provide reliable filtration for years to come.

In conclusion, 120 micron screens are an excellent choice for improving the filtration of medium-sized particles. These screens offer precise filtration capabilities, durability, and versatility, making them a popular choice in a wide range of industries. By selecting a high-quality 120 micron screen and using it correctly, you can achieve optimal filtration results and ensure the quality and purity of your products. Whether you are filtering water, chemicals, or other substances, a 120 micron screen can help you achieve the level of filtration you need for your specific application.

Tips for Maintaining and Cleaning 120 Micron Screens for Longevity

When it comes to filtration systems, 120 micron screens are a popular choice for capturing medium-sized particles. These screens are known for their reliability and efficiency in removing contaminants from various liquids and gases. However, like any filtration system, proper maintenance and cleaning are essential to ensure optimal performance and longevity.

One of the key tips for maintaining 120 micron screens is to regularly inspect them for any signs of damage or clogging. Over time, particles can build up on the screen, reducing its effectiveness and potentially causing damage. By inspecting the screens on a regular basis, you can identify any issues early on and take the necessary steps to address them before they become more serious.

In addition to regular inspections, it is important to clean 120 micron screens on a consistent basis. Cleaning the screens helps to remove built-up particles and debris, allowing them to function at their full capacity. There are several methods for cleaning 120 micron screens, including using a brush or a cleaning solution. It is important to follow the manufacturer’s recommendations for cleaning to ensure that the screens are not damaged in the process.

Another tip for maintaining 120 micron screens is to ensure that they are properly installed and secured. Screens that are not installed correctly can become loose or misaligned, which can impact their performance. By ensuring that the screens are securely in place, you can prevent any issues that may arise from improper installation.

It is also important to consider the environment in which the screens are being used. If the screens are exposed to harsh chemicals or extreme temperatures, they may require more frequent maintenance and cleaning. By understanding the specific conditions in which the screens are operating, you can take the necessary steps to ensure that they are properly maintained.

Regularly monitoring the performance of 120 micron screens is another important tip for maintaining their longevity. By keeping track of how well the screens are capturing particles and contaminants, you can identify any issues that may arise and address them promptly. Monitoring the performance of the screens can also help you to determine when it is time to replace them, ensuring that your filtration system continues to operate efficiently.

In conclusion, 120 micron screens are a reliable filtration option for capturing medium-sized particles. By following these tips for maintaining and cleaning the screens, you can ensure that they continue to perform at their best and have a long lifespan. Regular inspections, proper cleaning, secure installation, consideration of the operating environment, and monitoring performance are all essential steps in maintaining 120 micron screens for optimal filtration efficiency. By taking the time to care for your screens properly, you can enjoy the benefits of clean and contaminant-free liquids and gases for years to come.