Table of Contents

Benefits of Using 100um Filter Mesh for Precise Filtration Tasks

When it comes to precise filtration tasks, having the right equipment is essential. One such piece of equipment that is perfect for these tasks is the 100um filter mesh. This type of filter mesh is designed to provide a high level of filtration accuracy, making it ideal for applications where even the smallest particles need to be removed from a liquid or gas.

One of the key benefits of using a 100um filter mesh is its ability to capture particles as small as 100 microns in size. This level of filtration precision is crucial in industries such as pharmaceuticals, food and beverage, and electronics manufacturing, where even the tiniest contaminants can have a significant impact on product quality and safety.

In addition to its high level of filtration accuracy, the 100um filter mesh also offers excellent flow rates. This means that it can effectively remove particles from a liquid or gas stream without causing a significant drop in pressure. This is important in applications where maintaining a consistent flow rate is essential, as it ensures that the filtration process does not slow down or become inefficient.

Another benefit of using a 100um filter mesh is its durability. Made from high-quality materials such as stainless steel or nylon, this type of filter mesh is designed to withstand harsh operating conditions and frequent use. This means that it can provide reliable filtration performance over an extended period of time, reducing the need for frequent replacements and maintenance.

Furthermore, the 100um filter mesh is easy to clean and maintain, making it a cost-effective option for businesses looking to reduce their operating expenses. By simply rinsing or soaking the filter mesh in a cleaning solution, users can remove trapped particles and restore its filtration efficiency. This not only extends the lifespan of the filter mesh but also ensures that it continues to deliver optimal performance.

In conclusion, the 100um filter mesh is the perfect fit for precise filtration tasks due to its high level of filtration accuracy, excellent flow rates, durability, and ease of maintenance. Whether you are working in the pharmaceutical, food and beverage, or electronics manufacturing industry, this type of filter mesh can help you achieve the level of filtration precision you need to ensure product quality and safety. Consider investing in a 100um filter mesh for your filtration needs and experience the benefits it has to offer.

Applications of 100um Filter Mesh in Various Industries

100um filter mesh is a versatile tool that finds applications in a wide range of industries due to its ability to provide precise filtration. From pharmaceuticals to food and beverage production, this type of filter mesh plays a crucial role in ensuring the quality and purity of the final product. In this article, we will explore some of the key applications of 100um filter mesh in various industries.

In the pharmaceutical industry, maintaining the purity of drugs and medications is of utmost importance. Any impurities or contaminants can have serious consequences for patients. 100um filter mesh is commonly used in pharmaceutical manufacturing processes to remove particles and debris from liquids and gases. By using this fine mesh, pharmaceutical companies can ensure that their products meet the highest standards of quality and safety.

In the food and beverage industry, 100um filter mesh is also widely used to ensure the purity of products. Whether it’s filtering out impurities from fruit juices or removing particles from beer during the brewing process, this type of filter mesh is essential for maintaining the quality of food and beverage products. By using 100um filter mesh, food and beverage manufacturers can ensure that their products are free from contaminants and meet regulatory standards.

Another industry where 100um filter mesh is commonly used is the automotive industry. In automotive manufacturing, precision is key, and any contaminants in lubricants or fluids can cause serious damage to engines and other components. By using 100um filter mesh, automotive manufacturers can remove particles and debris from fluids, ensuring that their products meet the highest standards of quality and performance.

In the electronics industry, where even the smallest particles can cause malfunctions in electronic devices, 100um filter mesh is used to ensure the purity of chemicals and solvents used in manufacturing processes. By filtering out impurities with this fine mesh, electronics manufacturers can prevent defects in their products and ensure that they meet the strict quality standards of the industry.

In the water treatment industry, 100um filter mesh is used to remove particles and contaminants from water, ensuring that it is safe for consumption. Whether it’s filtering out sediment from drinking water or removing impurities from industrial wastewater, this type of filter mesh plays a crucial role in ensuring the purity of water for various applications.

Overall, 100um filter mesh is a versatile tool that finds applications in a wide range of industries where precise filtration is required. From pharmaceuticals to food and beverage production, automotive manufacturing to electronics, and water treatment, this type of filter mesh plays a crucial role in ensuring the quality and purity of products. By using 100um filter mesh, industries can maintain the highest standards of quality and safety in their products, making it an essential tool for various applications.

How to Choose the Right 100um Filter Mesh for Your Filtration Needs

When it comes to filtration tasks that require precision and accuracy, a 100um filter mesh is often the perfect fit. This type of filter mesh is designed to capture particles that are 100 microns or larger in size, making it ideal for a wide range of applications where fine filtration is necessary. Whether you are working in the pharmaceutical, food and beverage, or chemical industries, choosing the right 100um filter mesh is crucial to ensuring the success of your filtration process.

One of the key factors to consider when choosing a 100um filter mesh is the material it is made from. Different materials offer varying levels of durability, chemical resistance, and temperature tolerance, so it is important to select a material that is suitable for your specific filtration needs. Common materials used for 100um filter mesh include stainless steel, nylon, and polyester, each with its own set of advantages and disadvantages.

Stainless steel filter mesh is known for its strength and durability, making it a popular choice for applications where the filter will be subjected to high pressure or abrasive materials. Stainless steel filter mesh is also resistant to corrosion, making it suitable for use in harsh chemical environments. However, stainless steel filter mesh can be more expensive than other materials, so it may not be the best choice for budget-conscious filtration tasks.

nylon filter mesh is another popular choice for 100um filtration tasks. Nylon is lightweight, flexible, and resistant to abrasion, making it ideal for applications where the filter mesh needs to be manipulated or bent to fit into tight spaces. Nylon filter mesh is also resistant to most chemicals, making it a versatile option for a wide range of filtration tasks. However, nylon filter mesh may not be as durable as stainless steel, so it may not be suitable for applications where the filter will be subjected to high pressure or extreme temperatures.

Polyester filter mesh is a cost-effective option for 100um filtration tasks. Polyester is lightweight, flexible, and resistant to most chemicals, making it a versatile choice for a variety of applications. Polyester filter mesh is also easy to clean and maintain, making it a convenient option for filtration tasks that require frequent filter changes. However, polyester filter mesh may not be as durable as stainless steel or nylon, so it may not be suitable for applications where the filter will be subjected to harsh conditions.

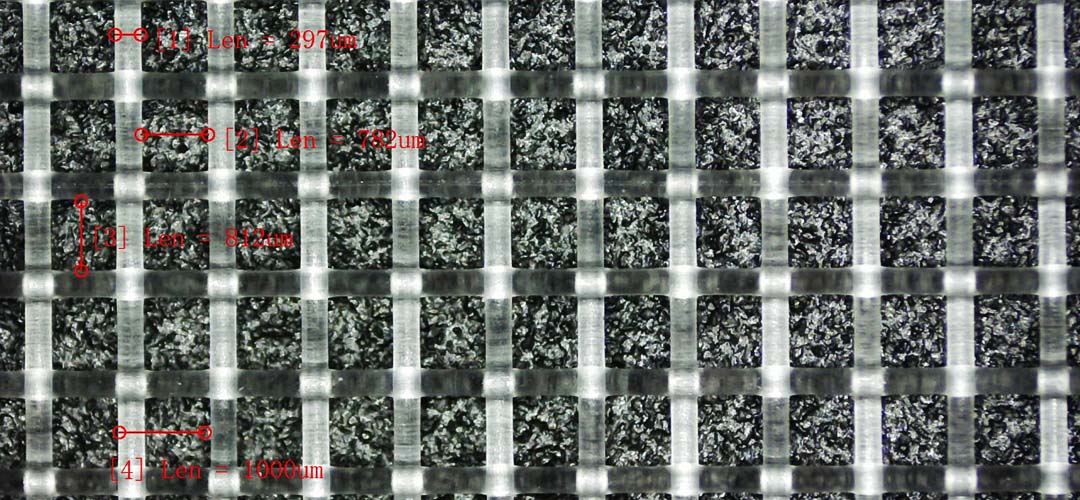

In addition to considering the material of the filter mesh, it is also important to consider the weave pattern of the mesh. The weave pattern of the mesh determines the size and shape of the openings in the mesh, which in turn affects the efficiency of the filtration process. Common weave patterns for 100um filter mesh include plain weave, twill weave, and Dutch weave, each offering its own set of advantages and disadvantages.

Plain weave filter mesh is the most common weave pattern and is characterized by a simple over-under pattern that creates a uniform mesh with square openings. Plain weave filter mesh is easy to clean and maintain, making it a convenient option for filtration tasks that require frequent filter changes. However, plain weave filter mesh may not offer the same level of precision as other weave patterns, so it may not be suitable for applications where fine filtration is necessary.

Twill weave filter mesh is characterized by a diagonal pattern that creates a tighter mesh with rectangular openings. Twill weave filter mesh offers better particle retention than plain weave mesh, making it ideal for applications where fine filtration is necessary. However, twill weave filter mesh may be more prone to clogging than plain weave mesh, so it may require more frequent cleaning and maintenance.

Dutch weave filter mesh is characterized by a combination of fine and coarse wires that create a dense mesh with rectangular openings. Dutch weave filter mesh offers the highest level of particle retention and is ideal for applications where precise filtration is necessary. However, Dutch weave filter mesh may be more expensive than other weave patterns, so it may not be the best choice for budget-conscious filtration tasks.

In conclusion, choosing the right 100um filter mesh for your filtration needs is crucial to ensuring the success of your filtration process. By considering factors such as material, weave pattern, and application requirements, you can select a filter mesh that is tailored to your specific needs. Whether you choose stainless steel, nylon, or polyester filter mesh, and whether you opt for a plain weave, twill weave, or Dutch weave pattern, selecting the right filter mesh will help you achieve precise and accurate filtration results.