Table of Contents

Benefits of Using 100um Filter Mesh in Industrial Applications

In the world of industrial filtration, the use of high-quality filter mesh is essential for ensuring reliable and efficient filtration processes. One of the most advanced designs in filter mesh technology is the 100um filter mesh, which offers a range of benefits for industrial applications.

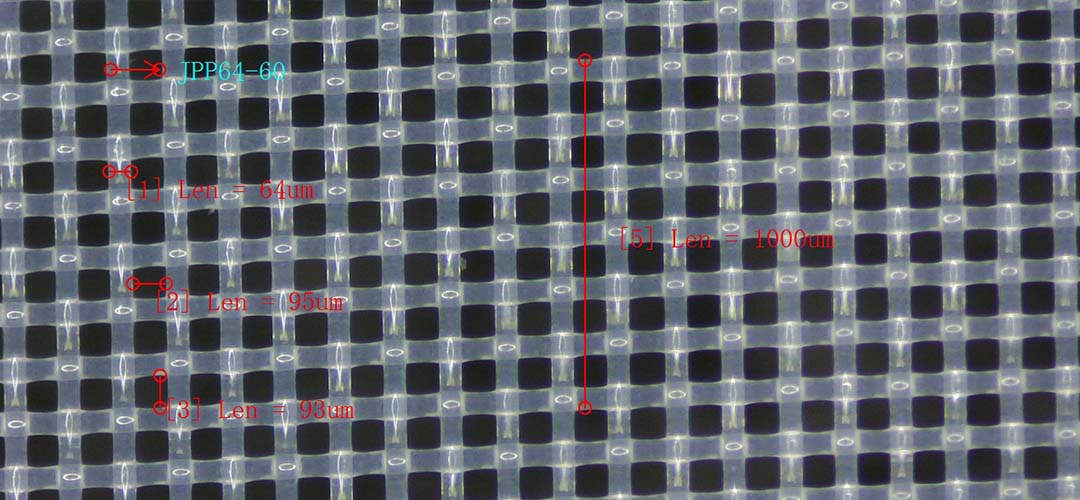

One of the key benefits of using 100um filter mesh is its superior filtration efficiency. With a mesh size of 100 microns, this type of filter mesh is capable of capturing even the smallest particles and contaminants, ensuring that the final product is free from impurities. This level of filtration efficiency is crucial in industries such as pharmaceuticals, food and beverage, and electronics, where product purity is of utmost importance.

Another advantage of 100um filter mesh is its durability and longevity. Made from high-quality materials such as stainless steel or nylon, this type of filter mesh is designed to withstand harsh operating conditions and frequent use. This means that industrial processes can run smoothly and efficiently without the need for frequent filter replacements, saving both time and money in the long run.

Furthermore, 100um filter mesh offers excellent flow rates, allowing for fast and efficient filtration processes. This is particularly important in industries where time is of the essence, such as in the production of pharmaceuticals or chemicals. With 100um filter mesh, industrial processes can be completed quickly and efficiently, leading to increased productivity and profitability.

In addition to its filtration efficiency, durability, and flow rates, 100um filter mesh is also highly versatile and can be customized to meet the specific needs of different industries. Whether it is used for removing contaminants from liquids, gases, or solids, this type of filter mesh can be tailored to achieve the desired level of filtration and purity. This flexibility makes 100um filter mesh a valuable asset in a wide range of industrial applications.

Moreover, the use of 100um filter mesh can also help companies meet regulatory requirements and quality standards. By ensuring that products are free from impurities and contaminants, businesses can avoid costly fines and penalties, as well as protect their reputation and brand image. With 100um filter mesh, companies can rest assured that their products meet the highest standards of quality and purity.

Overall, the benefits of using 100um filter mesh in industrial applications are clear. From its superior filtration efficiency and durability to its fast flow rates and versatility, this type of filter mesh offers a range of advantages for businesses looking to improve their filtration processes. By investing in high-quality 100um filter mesh, companies can achieve reliable and efficient filtration, leading to increased productivity, profitability, and compliance with regulatory standards.

How to Choose the Right 100um Filter Mesh for Your Filtration Needs

When it comes to choosing the right filter mesh for your filtration needs, there are a few key factors to consider. One of the most important considerations is the size of the particles you need to filter out. For many applications, a 100um filter mesh is an ideal choice. This size is small enough to capture most particles of interest while still allowing for good flow rates.

One of the key advantages of a 100um filter mesh is its advanced design. These meshes are typically made from high-quality materials that are designed to withstand the rigors of filtration. They are often constructed with precision to ensure that the mesh is uniform and free from defects that could compromise its effectiveness.

In addition to their advanced design, 100um filter meshes are also known for their reliability. These meshes are able to consistently filter out particles of a certain size, making them a dependable choice for a wide range of applications. Whether you are filtering water, chemicals, or other substances, a 100um filter mesh can provide the reliable filtration you need.

Another important factor to consider when choosing a 100um filter mesh is the material it is made from. Different materials offer different levels of durability and chemical resistance, so it is important to choose a mesh that is compatible with the substances you will be filtering. Stainless steel is a popular choice for filter meshes due to its strength and corrosion resistance, but other materials such as nylon and polyester are also commonly used.

When selecting a 100um filter mesh, it is also important to consider the weave pattern. The weave pattern of a mesh can affect its filtration efficiency, flow rate, and durability. Common weave patterns for filter meshes include plain weave, twill weave, and Dutch weave. Each of these patterns has its own advantages and disadvantages, so it is important to choose the one that best suits your filtration needs.

In addition to the size, material, and weave pattern of the mesh, it is also important to consider the construction of the filter. Some filters are designed to be disposable, while others are reusable and can be cleaned and reused multiple times. The type of filter construction you choose will depend on your specific needs and budget.

Overall, choosing the right 100um filter mesh for your filtration needs is essential for achieving reliable and efficient filtration. By considering factors such as size, material, weave pattern, and construction, you can select a filter mesh that meets your specific requirements. With its advanced design and reliable performance, a 100um filter mesh is a smart choice for a wide range of filtration applications.

Maintenance Tips for Ensuring Optimal Performance of 100um Filter Mesh

When it comes to maintaining optimal performance of your 100um filter mesh, there are a few key tips to keep in mind. This advanced design offers reliable filtration for a variety of applications, but proper maintenance is essential to ensure it continues to operate at peak efficiency.

One of the most important maintenance tips for your 100um filter mesh is regular cleaning. Over time, debris and contaminants can build up on the mesh, reducing its effectiveness. By regularly cleaning the filter mesh, you can prevent clogs and ensure that it continues to filter out particles effectively.

To clean your 100um filter mesh, start by removing it from its housing and rinsing it with clean water. You can use a soft brush or cloth to gently scrub away any stubborn debris. Be sure to rinse the mesh thoroughly to remove any remaining particles before reinstalling it in its housing.

In addition to regular cleaning, it’s also important to inspect your 100um filter mesh for any signs of damage. Tears or holes in the mesh can compromise its filtration capabilities, allowing contaminants to pass through unchecked. If you notice any damage, it’s important to replace the mesh as soon as possible to maintain optimal performance.

Another key maintenance tip for your 100um filter mesh is to monitor its pressure differential. As the mesh becomes clogged with debris, the pressure drop across the filter will increase. By monitoring the pressure drop regularly, you can identify when the filter needs to be cleaned or replaced before it impacts the performance of your system.

In addition to monitoring pressure drop, it’s also important to keep an eye on the flow rate through the filter. A decrease in flow rate can indicate a clogged filter mesh, which can lead to reduced filtration efficiency. By monitoring flow rate, you can identify when the filter needs to be cleaned or replaced to maintain optimal performance.

Finally, it’s important to follow the manufacturer’s recommendations for maintenance and replacement of your 100um filter mesh. Different filters may have different lifespans and maintenance requirements, so it’s important to follow the guidelines provided by the manufacturer to ensure that your filter continues to operate effectively.

In conclusion, proper maintenance is essential for ensuring optimal performance of your 100um filter mesh. By regularly cleaning the mesh, inspecting it for damage, monitoring pressure drop and flow rate, and following manufacturer recommendations, you can ensure that your filter continues to provide reliable filtration for your system. With these maintenance tips in mind, you can maximize the lifespan and efficiency of your 100um filter mesh for years to come.