Table of Contents

Benefits of Using 100 micron nylon mesh in Industrial Filtration Processes

When it comes to industrial filtration processes, having the right equipment is crucial to ensuring efficiency and effectiveness. One key component that is often overlooked but plays a significant role in the success of these processes is the mesh material used in filtration systems. One material that has proven to be versatile and durable for industrial needs is 100 micron nylon mesh.

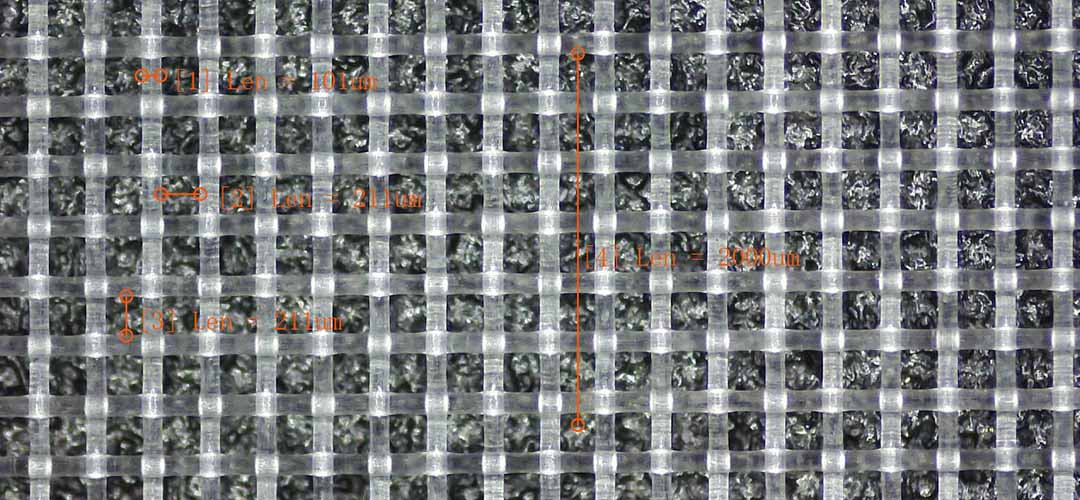

Nylon mesh is a synthetic material that is known for its strength, durability, and resistance to chemicals and abrasion. When woven into a mesh with a 100 micron opening size, it becomes an ideal choice for a wide range of industrial filtration applications. The small opening size of 100 microns allows for the filtration of fine particles while still maintaining a high flow rate, making it suitable for a variety of industries, including pharmaceuticals, food and beverage, and chemical processing.

One of the key benefits of using 100 micron nylon mesh in industrial filtration processes is its versatility. This material can be used in a variety of filtration systems, including filter bags, filter discs, and filter screens. Its flexibility allows for easy customization to fit the specific needs of different applications, making it a cost-effective solution for many industries.

In addition to its versatility, 100 micron nylon mesh is also highly durable. Its resistance to chemicals and abrasion ensures that it can withstand harsh operating conditions without compromising its filtration efficiency. This durability translates to longer service life and reduced maintenance costs, making it a reliable choice for industrial filtration systems.

Another advantage of using 100 micron nylon mesh is its ease of cleaning and maintenance. Unlike some other filtration materials that require specialized cleaning procedures, nylon mesh can be easily cleaned with water or mild detergents, making it a low-maintenance option for industrial applications. This ease of maintenance helps to minimize downtime and ensure continuous operation of filtration systems.

Furthermore, 100 micron nylon mesh is an environmentally friendly option for industrial filtration. Nylon is a recyclable material, which means that it can be reused or repurposed at the end of its service life, reducing waste and promoting sustainability in industrial processes. By choosing nylon mesh for filtration applications, companies can demonstrate their commitment to environmental responsibility while still achieving high-quality filtration results.

In conclusion, 100 micron nylon mesh is a versatile and durable material that offers numerous benefits for industrial filtration processes. Its strength, durability, and resistance to chemicals make it an ideal choice for a wide range of applications, while its ease of maintenance and environmental friendliness further enhance its appeal. Whether used in filter bags, filter discs, or filter screens, nylon mesh can help companies achieve efficient and effective filtration results while reducing maintenance costs and promoting sustainability. For industrial needs that require reliable and high-performance filtration, 100 micron nylon mesh is a smart choice.

How 100 Micron Nylon Mesh Can Improve Efficiency in Paint and Coating Applications

When it comes to industrial applications, efficiency is key. Whether you are in the paint and coating industry or another sector that requires filtration and separation processes, having the right tools and materials can make all the difference. One such material that has proven to be versatile and durable for a wide range of industrial needs is 100 micron nylon mesh.

Nylon mesh is a popular choice for many industries due to its strength, flexibility, and resistance to chemicals and abrasion. The 100 micron size is particularly useful for applications that require fine filtration and separation. This mesh size is ideal for capturing small particles and ensuring a high level of precision in the filtration process.

In the paint and coating industry, the use of 100 micron nylon mesh can greatly improve efficiency and quality. When applying paint or coating materials, it is essential to have a consistent and uniform finish. The use of nylon mesh can help to achieve this by ensuring that the paint or coating is free of any impurities or contaminants that could affect the final result.

Additionally, nylon mesh is easy to clean and maintain, making it a cost-effective solution for industrial applications. Its durability and longevity mean that it can withstand repeated use without losing its effectiveness. This makes it a reliable choice for businesses looking to streamline their processes and reduce downtime.

Another benefit of using 100 micron nylon mesh in paint and coating applications is its versatility. Nylon mesh can be customized to fit specific requirements, making it suitable for a wide range of applications. Whether you need a mesh that is heat-resistant, chemical-resistant, or anti-static, nylon mesh can be tailored to meet your needs.

Furthermore, nylon mesh is lightweight and easy to handle, making it a practical choice for industrial settings. Its flexibility allows for easy installation and removal, saving time and effort during the filtration process. This can lead to increased productivity and efficiency in the workplace.

In conclusion, 100 micron nylon mesh is a versatile and durable material that can greatly improve efficiency in paint and coating applications. Its fine filtration capabilities, durability, and versatility make it an ideal choice for businesses looking to enhance their processes and achieve a high level of quality in their products. By investing in nylon mesh, businesses can benefit from increased productivity, reduced downtime, and improved overall performance.

The Versatility of 100 Micron Nylon Mesh in Separation and Sieving Processes

100 Micron Nylon Mesh is increasingly recognized for its versatility and durability, particularly in industrial applications involving separation and sieving processes. This fine mesh material, characterized by its 100-micron openings, offers a unique combination of strength and flexibility, making it an ideal choice for various industries, including food processing, pharmaceuticals, and chemical manufacturing. The ability to effectively separate particles of different sizes is crucial in these sectors, and 100 Micron Nylon Mesh excels in this regard.

One of the primary advantages of using 100 Micron Nylon Mesh is its exceptional filtration capabilities. The mesh can efficiently filter out contaminants while allowing desired materials to pass through, ensuring high purity levels in the final product. This is particularly important in the food industry, where maintaining hygiene and safety standards is paramount. The nylon material is resistant to many chemicals, which enhances its utility in environments where exposure to harsh substances is common. As a result, manufacturers can rely on this mesh to perform consistently, even under challenging conditions.

Moreover, the durability of 100 Micron Nylon Mesh contributes significantly to its versatility. Unlike other materials that may degrade or lose their structural integrity over time, nylon mesh maintains its performance characteristics, providing a long-lasting solution for separation and sieving needs. This durability translates into cost savings for businesses, as they can reduce the frequency of replacements and maintenance. Additionally, the mesh is lightweight, which facilitates easy handling and installation, further enhancing its appeal in various applications.

In the realm of sieving, 100 Micron Nylon Mesh is particularly effective in applications requiring precise particle size separation. Industries that deal with powders, granules, or liquids benefit from the mesh’s ability to create uniform particle distributions. This is essential for processes such as coating, where the consistency of the material affects the quality of the final product. By utilizing 100 Micron Nylon Mesh, companies can achieve the desired specifications with greater accuracy, leading to improved operational efficiency.

Furthermore, the versatility of this mesh extends to its adaptability in different configurations. It can be used in various forms, such as bags, sheets, or custom-designed filters, allowing businesses to tailor their separation processes to specific requirements. This flexibility is particularly advantageous in industries where processes may vary significantly from one application to another. By employing 100 Micron Nylon Mesh, companies can streamline their operations and enhance productivity, as the mesh can be easily integrated into existing systems.

Another noteworthy aspect of 100 Micron Nylon Mesh is its ease of cleaning and maintenance. In industries where hygiene is critical, the ability to quickly and effectively clean the mesh is a significant benefit. The nylon material can withstand repeated washings without losing its structural integrity, ensuring that it remains a reliable tool for separation and sieving tasks. This ease of maintenance not only contributes to operational efficiency but also supports compliance with industry regulations regarding cleanliness and safety.

In conclusion, the versatility and durability of 100 Micron Nylon Mesh make it an invaluable asset in various industrial separation and sieving processes. Its exceptional filtration capabilities, combined with its resistance to chemicals and ease of maintenance, position it as a preferred choice for businesses seeking reliable and efficient solutions. As industries continue to evolve and demand higher standards of quality and efficiency, the role of 100 Micron Nylon Mesh will undoubtedly become even more prominent, solidifying its place as a cornerstone in industrial applications.