Table of Contents

Benefits of Using 1 micron stainless steel mesh for Filtration

When it comes to filtration, precision is key. Whether you are working in the pharmaceutical, food and beverage, or chemical industry, having the right filtration system in place is crucial for ensuring the quality and purity of your products. One of the most effective materials for filtration is stainless steel mesh, particularly 1 micron stainless steel mesh. This ultra-fine mesh offers exceptional filtration precision, making it ideal for a wide range of applications.

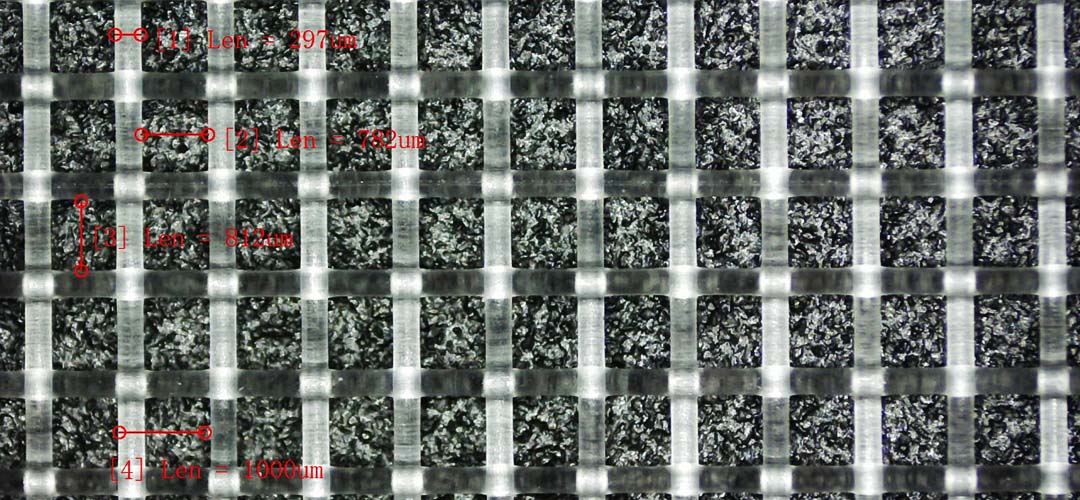

1 micron stainless steel mesh is designed to capture particles as small as 1 micron in size. To put that into perspective, a human hair is typically around 70 microns in diameter, so 1 micron mesh is incredibly fine. This level of precision allows for the removal of even the smallest contaminants from liquids and gases, ensuring that the final product is of the highest quality.

One of the key benefits of using 1 micron stainless steel mesh for filtration is its durability. Stainless steel is known for its strength and corrosion resistance, making it ideal for use in harsh industrial environments. Unlike other materials, such as plastic or nylon, stainless steel mesh can withstand high temperatures, pressures, and chemical exposure without degrading. This means that you can rely on 1 micron stainless steel mesh to provide consistent and reliable filtration performance over time.

In addition to its durability, 1 micron stainless steel mesh offers excellent flow rates. The fine mesh size allows for efficient filtration without impeding the flow of liquid or gas through the system. This is important for maintaining productivity and minimizing downtime in industrial processes. With 1 micron stainless steel mesh, you can achieve the level of filtration precision you need without sacrificing flow rates.

Another advantage of using 1 micron stainless steel mesh is its versatility. This type of mesh can be used in a wide range of applications, from water and air filtration to pharmaceutical and food processing. Whether you are filtering out particles, separating solids from liquids, or removing impurities from gases, 1 micron stainless steel mesh can meet your needs. Its flexibility and adaptability make it a valuable tool for a variety of industries.

Furthermore, 1 micron stainless steel mesh is easy to clean and maintain. Unlike disposable filters that need to be replaced frequently, stainless steel mesh can be cleaned and reused multiple times. This not only reduces waste and saves money but also ensures consistent filtration performance. With proper care and maintenance, 1 micron stainless steel mesh can last for years, providing long-term value for your filtration system.

In conclusion, 1 micron stainless steel mesh offers exceptional filtration precision, durability, flow rates, versatility, and ease of maintenance. Whether you are looking to improve the quality of your products, increase productivity, or reduce operating costs, using 1 micron stainless steel mesh for filtration can help you achieve your goals. Invest in the best filtration solution for your business with 1 micron stainless steel mesh.

Applications of 1 Micron Stainless Steel Mesh in Various Industries

1 Micron Stainless Steel Mesh for Exceptional Filtration Precision

In the world of filtration, precision is key. Whether it’s removing impurities from liquids or separating particles in a gas stream, having the right filter can make all the difference. That’s where 1 micron stainless steel mesh comes in. With its fine mesh size and durable construction, this material is perfect for applications that require exceptional filtration precision.

One of the key benefits of using 1 micron stainless steel mesh is its ability to capture even the smallest particles. With a mesh size of just 1 micron, this material can effectively filter out particles that are invisible to the naked eye. This makes it ideal for industries that require high levels of purity, such as pharmaceuticals, food and beverage, and electronics manufacturing.

Another advantage of 1 micron stainless steel mesh is its durability. Made from high-quality stainless steel, this material is resistant to corrosion, abrasion, and high temperatures. This means that it can withstand harsh operating conditions without losing its effectiveness. In addition, stainless steel mesh is easy to clean and maintain, making it a cost-effective filtration solution for businesses looking to reduce downtime and maintenance costs.

The versatility of 1 micron stainless steel mesh also makes it a popular choice for a wide range of industries. From wastewater treatment to oil and gas production, this material can be used in a variety of applications to achieve precise filtration results. In the automotive industry, for example, stainless steel mesh is used to filter out contaminants in engine oil and fuel systems, ensuring optimal performance and longevity of vehicle components.

In the aerospace industry, 1 micron stainless steel mesh is used in hydraulic systems to remove particles that could cause damage to sensitive equipment. By using a filter with such fine mesh size, aerospace manufacturers can ensure that their systems operate at peak efficiency and safety standards. Similarly, in the chemical industry, stainless steel mesh is used to separate solids from liquids in chemical processing plants, preventing contamination and ensuring product quality.

Overall, the applications of 1 micron stainless steel mesh are vast and varied, making it an essential component in many industries. Its ability to provide exceptional filtration precision, durability, and versatility make it a valuable investment for businesses looking to improve their filtration processes. Whether it’s removing impurities from liquids, separating particles in a gas stream, or ensuring the purity of a product, stainless steel mesh is a reliable and effective solution.

In conclusion, 1 micron stainless steel mesh is a powerful tool for achieving exceptional filtration precision in a wide range of industries. Its fine mesh size, durability, and versatility make it an ideal choice for businesses looking to improve their filtration processes and ensure the quality of their products. By investing in stainless steel mesh, companies can benefit from increased efficiency, reduced maintenance costs, and improved product quality.

How to Choose the Right 1 Micron Stainless Steel Mesh for Your Filtration Needs

When it comes to filtration, precision is key. Whether you are in the pharmaceutical, food and beverage, or chemical industry, having the right filtration system in place is crucial for maintaining product quality and ensuring regulatory compliance. One of the most popular choices for filtration is 1 micron stainless steel mesh. This type of mesh offers exceptional filtration precision, making it ideal for a wide range of applications.

When choosing the right 1 micron stainless steel mesh for your filtration needs, there are several factors to consider. The first thing to look at is the material of the mesh. Stainless steel is a popular choice for filtration due to its durability, corrosion resistance, and high temperature resistance. When selecting a stainless steel mesh, make sure it is made from high-quality stainless steel to ensure long-lasting performance.

Another important factor to consider is the weave of the mesh. The weave of the mesh determines the size of the openings and the amount of material that can pass through. For 1 micron filtration, a tight weave is essential to ensure that even the smallest particles are captured. Look for a mesh with a plain weave or twill weave for optimal filtration efficiency.

In addition to the material and weave, the construction of the mesh is also important. The mesh should be tightly woven and securely bonded to ensure that it can withstand high pressure and maintain its filtration precision over time. Look for a mesh that is reinforced with a sturdy frame or backing to prevent sagging or stretching during use.

When choosing a 1 micron stainless steel mesh, it is also important to consider the size and shape of the particles you are trying to filter. Different applications may require different mesh sizes and configurations to achieve the desired level of filtration. Consult with a filtration expert to determine the best mesh size and configuration for your specific needs.

In addition to the technical specifications of the mesh, it is also important to consider the overall quality and reputation of the manufacturer. Look for a reputable supplier with a track record of providing high-quality filtration products and excellent customer service. A reliable supplier will be able to provide guidance on selecting the right mesh for your application and offer support throughout the purchasing process.

In conclusion, choosing the right 1 micron stainless steel mesh for your filtration needs is essential for achieving optimal filtration precision. Consider factors such as material, weave, construction, particle size, and supplier reputation when selecting a mesh for your application. With the right mesh in place, you can ensure that your filtration system operates efficiently and effectively, providing clean and pure products for your customers.